Ask Jillian: How Do I Keep My Colors Clear in Chain Ply?

I am so frustrated that the colors in my chain-plied yarn keep combining. I want my yarn to look as close to my hand-dyed braid as possible. Tell me how to keep my colors clear and unmarled. ~Donna, Harrisville, NH

Hi Donna,

I hate when that happens! The number one reason that I chain ply is to keep my hand-dyed braid color clear and unmixed with others. Last month Jacey got us started with chain plying; now let’s fine tune for clearer color.

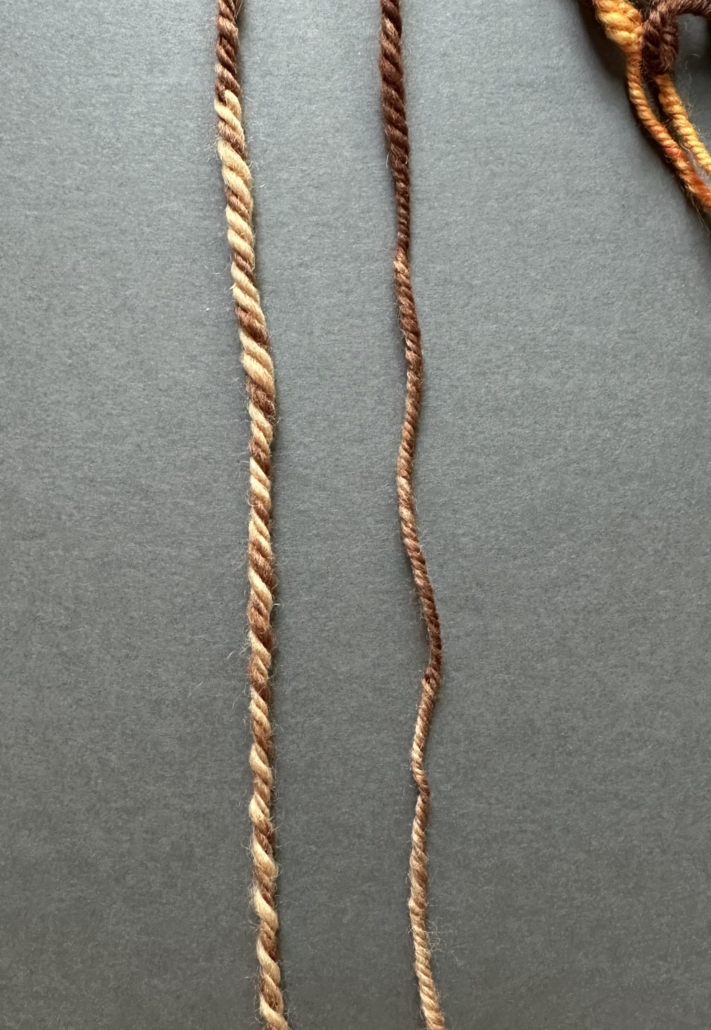

I want my yarns to look more like the small skein on the right than the one on the left.

I love the motion of chain plying because it’s so relaxing, but I found if I change a couple of things I get clearer colors.

I slow down, pay attention to where the color changes are, and use a variety of loop sizes while I ply.

My usual chain-ply loop is the size of an orange, sometimes bigger. I can happily ply along for an entire bobbin with loops of that size. But when I keep my loops the same, on the bigger side, my colors mix and marl when colors transition.

I taught myself to make loops about the size of a chubby grape, and I use those smaller loops when the colors change in my singles. The yarn will still barber pole, but the length of the marled section is much smaller, the size of the smaller loop.

I do have to slow my roll when I treadle and watch my singles to see when the colors change, but that extra time is worth it to me for the colors I want. I usually use two or three smaller loops right before the color change, one at the color change, and two or three after the color change.

It’s not 100 percent perfect; a lot of the time colors will marl while drafting singles and those will marl in the ply. Comparing the yarn on the left that has large loops and a long stretch of marled colors to the yarn on the right, where I used a combination of loop sizes, I like the flow of the smaller amounts of marled yarn much more.

I try not to fet too much about the small parts that do marl. I can see them when I look closely, but when I look at my yarn as a whole skein, the overall look is clear, beautiful color.

Want Jillian or Jacey to take a stab at your question? Tell us what you want to know: