Dehairing Cashmere by Hand

Words & Photos by Meagan Condon

If there is one thing I can say about librarians, it’s that they’re in the business of enabling people. Do you need the latest James Patterson novel? They’ve got you. How about an article from the July 24, 1972, issue of Time magazine? A librarian has your back. My colleagues at the library know of my passion for fiber arts and are often eager to provide me with any “reference material” they come across, as was the case when I found a ziplock bag full of hair stashed in my staff mailbox. The name “Blackie” was sharpied across the top. Blackie was a goat – and not a special type of goat – just your generic, crossbred farm goat used for clearing brush. My teammate, who lived on a farm outside of town, had brushed out his winter coat and figured I might want it. Well, why not?

This particular fiber from Blackie was cashmere. While there are specific breeds of goats generally associated with cashmere production, almost all goats produce a soft, downy undercoat. For most breeds, there is less usable fiber and more guard hair, which can make it a nightmare to prepare by hand. Many would choose not to use the term cashmere here, as there are strict industry guidelines for classifying commercial cashmere. Ultimately, we’re talking about the same fiber, though. Let’s talk about preparing this “inferior” cashmere for spinning.

The first task at hand is to dehair the cashmere. This means to remove all guard hairs in the fiber. Guard hair is usually longer, is coarser, lacks crimp, and will be black or white in color. It is nothing like the soft fluff we’re looking for, and it is pretty easy to spot. If I were to spin it into my yarn, it would make the yarn prickly, cause all kinds of neps, and be generally unpleasant. Some mills offer a dehairing service, but it can cost an additional $10–20 per pound, and there is usually a minimum quantity of fiber they will accept, often in the 2–10 pound range. If you’re like me and only have a few ounces, this isn’t an option.

Instead, we have the herculean task of removing the guard hair by hand. How does one go about removing all those tiny hairs? While there are several tricks you can try to make the process easier, I’ve found that the quickest way to process cashmere is to skip the tricks, grab a pair of tweezers, and get to work. Fingers work just as well, in a pinch.

Pinch off a small amount of fiber. You’ll be able to see the guard hairs poking out in all directions. Start removing them. Then, when you don’t see any more guard hairs, turn your fiber over, fold the fiber in half, and look again. As you fold the fiber, the less-flexible guard hairs aren’t as willing to fold and will poke out. When you don’t see any more guard hairs, stretch the fiber open into a thin web and look at it with a light behind it. This should reveal any remaining unsavory bits.

After a session of dehairing, my fingers are almost completely black with dirt. Remember, these animals roll around in the dirt and who-knows-what to cool down and keep bugs away. Even so, I find it easiest to dehair the fiber before washing and spinning it. Every time I’ve tried to wash the fiber first, it has been impossible to dehair and work with later. The fiber is prone to pilling or felting in the wash.

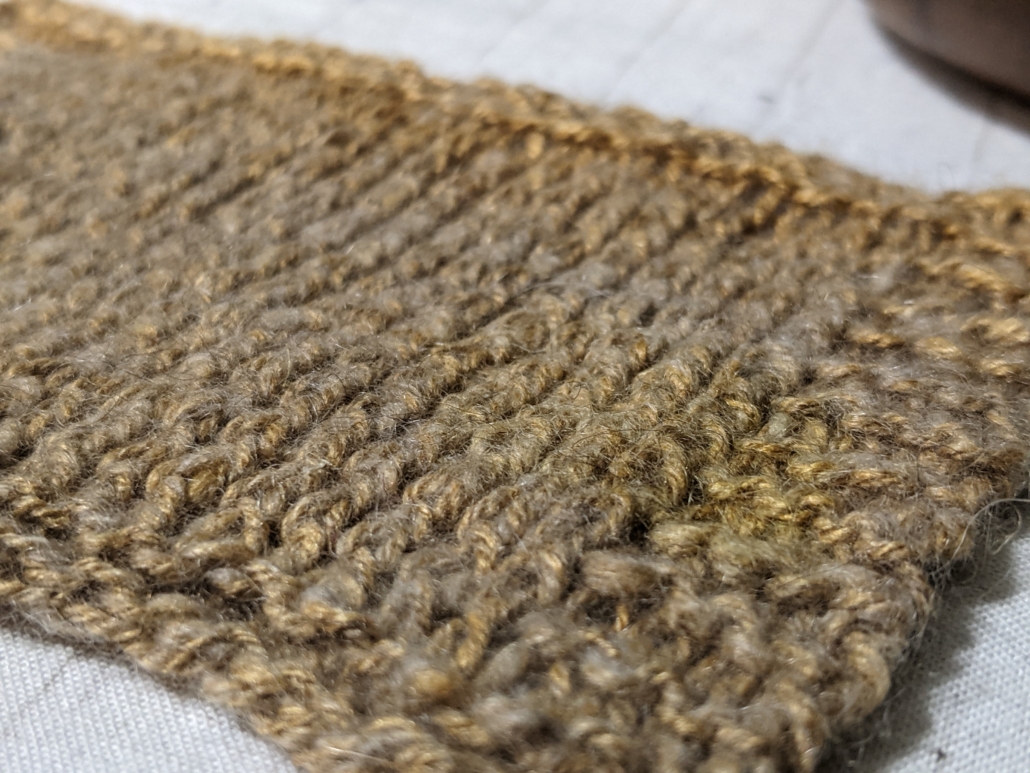

Once the hair has been removed, what is left is a beautiful cloud of spinnable joy. Sometimes I spin straight from the cloud. Sometimes I card the fiber into rolags using a fine carding cloth or cotton carders. For Blackie’s special fiber, I blended it 50/50 with muga silk. The delicate, gold silk matched the warm undertones in Blackie’s fiber perfectly. What’s not to love about a cashmere/silk blend, anyway? While carding, I was careful not to overwork the fiber by passing it over my carders too many times. As I mentioned before, cashmere is prone to pilling and I didn’t want to lose the luxury of the fiber through my own careless preparation. One or two passes with the carders is enough.

I then spun the rolags using an American longdraw technique on my Ashford Joy II at a ratio of 11:1 with low brake band tension. I think cashmere craves being spun with a woolen preparation and technique. The short, fine fibers are ideal for the technique. This is the point in the process I wash the yarn, soaking it in warm water multiple times, until the water runs clear. I also treat it to some rough handling and snapping to cause the halo to bloom.

The resulting yarn has a fine halo and matte appearance. When paired with the shine of the muga silk, which lies just beneath the halo, the yarn ends up having a depth of texture and color which the cashmere just doesn’t have on its own.

Dehairing fiber by hand will never be my favorite task, but the value in this fiber has less to do with the fact that it boasts the title cashmere and everything to do with where it came from. Sometimes we spin for the joy of working with a particular type of fiber or a specific style or technique. Sometimes the history \ matters to us. No matter why we choose to spin, it always has to do with connection: connection with nature, with our past, with ourselves. In this case, the connection was Blackie, a sometimes-ornery goat who was a vital part of my colleague’s family . . . a goat who had been raised in the kitchen and who had grown up alongside my colleague’s daughter. That emotional connection made it some of the most valuable fiber I have ever spun.

Video with tips on dehairing cashmere: https://youtu.be/GTgOOoqjfhk

Meagan Condon is a librarian and fiber artist with more than a decade of spinning experience. She focuses on digital connection and teaches fiber arts across the midwest and online. You can follow her at luthvarian.com.

PLY Magazine believes that Black lives matter, as well as LBGTQI+ lives. Those most vulnerable and persecuted in our communities deserve our love and support. Please be good to each other.

Did you know we also have a monthly PLY newsletter? Sign up here!

Did you know we also have a monthly PLY newsletter? Sign up here!