By the Books: Using Older Texts to Inform Our Modern Understanding of Fiber

By Meagan Condon

I love the smell of old books. It is a smell that goes nicely with the smell of fresh fleece and hot coffee. My perfect afternoon would probably involve pivoting between scouring a fleece, one small bag at a time, and curling up in the living room next to a stack of old non-fiction books.

There seems to be a lot of crossover between book people and fiber people. It is part of why I spend so much time researching fiber arts. I love to play with fiber, but I am always looking for deeper meaning about how and why it behaves the way it does.

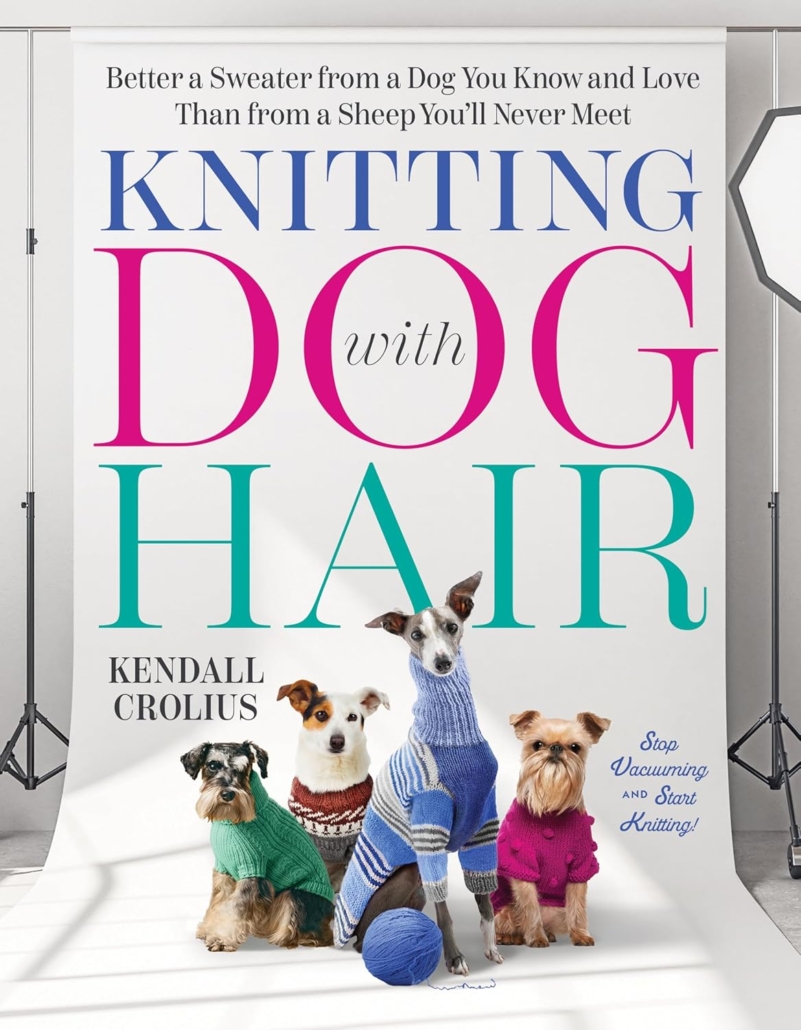

Right now, thanks to my local library, Sheep and Man by Michael L Ryder, an 856-page tome – and I do mean tome – published in the UK in 1983, sits half-read on my nightstand. Published more than 40 years ago, this book is touted by some to be the definitive work on the history of the domestication of sheep – which is interesting, considering it isn’t in publication and used copies are so rare they go for more than my car payment.

Definitive is a dangerous word, to me. It gives us the illusion that knowledge is finite and unchanging, neither of which is true. New science comes along and answers questions we didn’t have answers for, which changes our understanding of things we thought we knew. In the handspinning community, we are particularly at risk of thinking that the knowledge and history of the craft never changes. It worked 500 years ago, so it should work the same way today.

The truth is, as soon as something is published, it is outdated. As a general rule, I approach any text older than 10 years with this fact tucked neatly in the back of my mind, and as I read, I question just about every fact that I don’t already have a clear understanding of (and even some facts which I do).

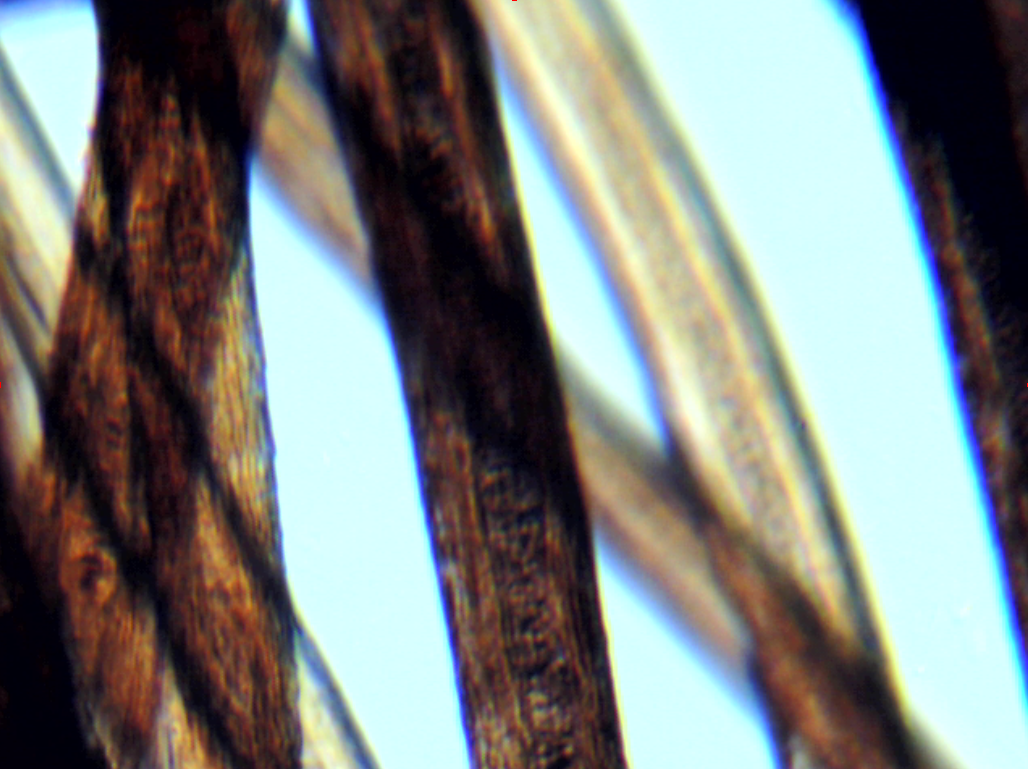

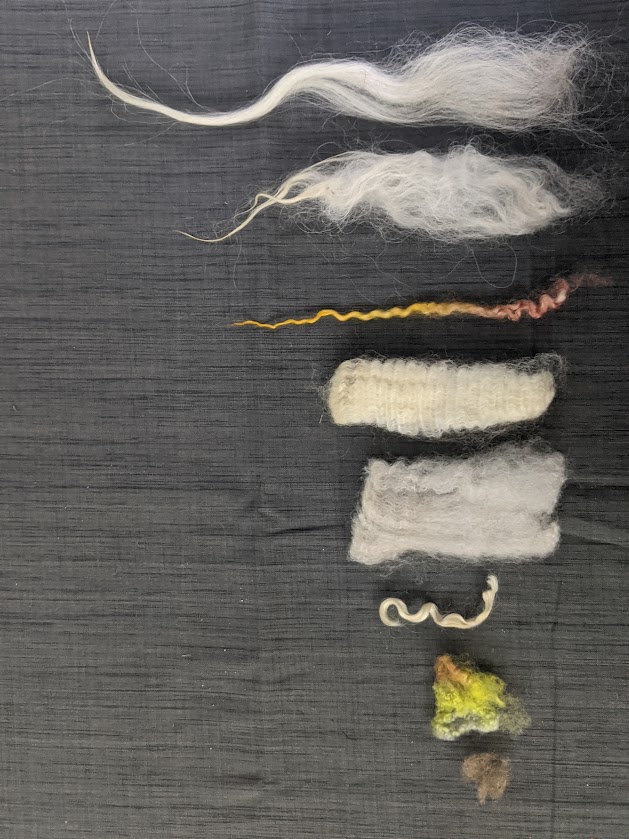

For example, Ryder points out that the proteins in sheep and goat wool are different, which indicates they likely diverged evolutionarily before they were domesticated. This made me curious – did more current microscopy and DNA analysis support this? So I set my book down, picked up my tablet, and began to research the difference between goat and sheep hair proteins.

In my further research, I learned that wool and cashmere are primarily made from keratin, the same protein our hair and nails are made from. However, they contained different keratin-associated proteins (KRTAPs) and the arrangement and amount of these additional proteins was different.

In fact, KRTAPs not only differed between ruminant species but also proved to be a determining factor in how fine, strong, and flexible a fiber is within a breed of sheep or goats.

This gave me additional information in support of what Ryder said four decades ago. Ryder didn’t have all the answers, though it would have been easy for me to just accept his word on the matter. After all, he was the expert! That said, his voice wasn’t able to give me the full picture of how goat and sheep hair differed. What it gave me was the right questions to ask.

An hour and a half diversion from my book, a fresh cup of coffee, and 4 tablespoons of wool wash later, and I can finally move to the next paragraph, page 19. I’ve got a long afternoon ahead of me.

References

Li S, Xi Q, Zhao F, Wang J, He Z, Hu J, Liu X, Luo Y. “A highly polymorphic caprine keratin-associated protein gene identified and its effect on cashmere traits.” J Anim Sci. 2021 Sep 1;99(9):skab233. doi: 10.1093/jas/skab233. PMID: 34370022; PMCID: PMC8442941.

Ryder, M. L. (2007). Sheep & Man. Duckworth.

Zhang C, Qin Q, Liu Z, Xu X, Lan M, Xie Y, Wang Z, Li J, Liu Z. “Identification of the key proteins associated with different hair types in sheep and goats.” Front Genet. 2022 Sep 23;13:993192. doi: 10.3389/fgene.2022.993192. PMID: 36212123; PMCID: PMC9539809.

Zhanzhao, Chen & Cao, Jian & Zhao, Fang & He, Zhaohua & Sun, Hongxian & Wang, Jiqing & Liu, Xiu & Li, Shaobin. (2023). “Identification of the Keratin-Associated Protein 22-2 Gene in the Capra hircus and Association of Its Variation with Cashmere Traits.” Animals. 13. 2806. 10.3390/ani13172806.