PLY Guild: Second Season Drop – Episode 3

I am thrilled to report that the third episode of the second (worsted) season of the PLY Guild has dropped and is almost ready for your viewing pleasure! It’ll be up on July 18th (we had a little family emergency and so it’s running behind 2-3 days).

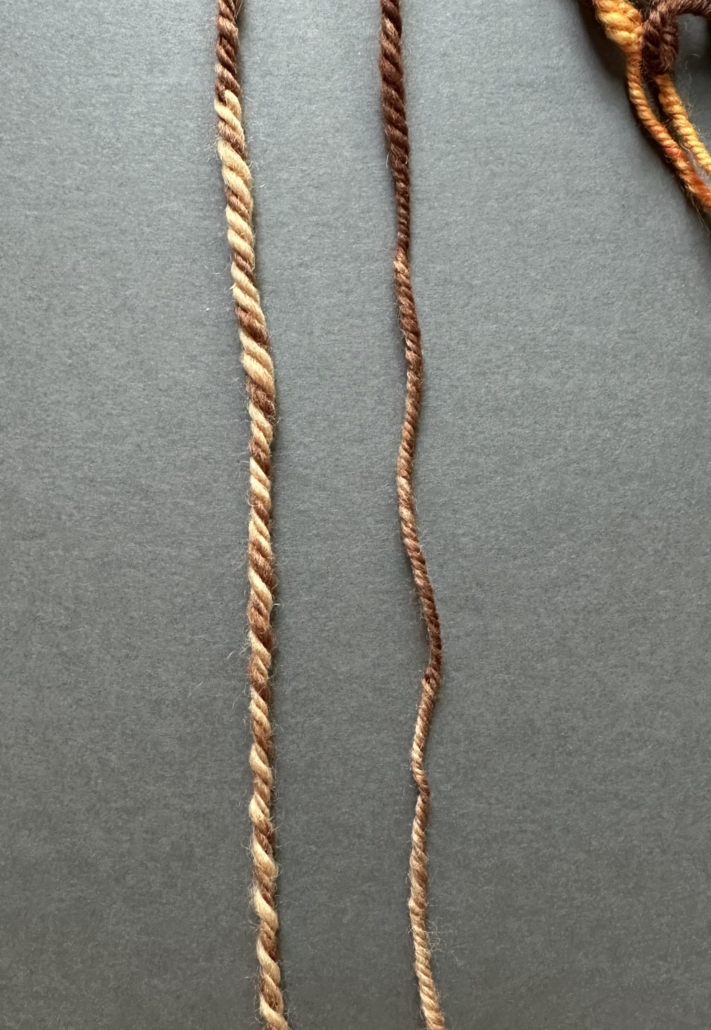

This episode is all about combs! You’ll learn how to choose combs and use combs from some great teachers including: Maggie Casey, Laura Linneman, Michelle Boyd, and Jacey Boggs Faulkner. We’ll cover 2-pitch Viking combs, 4-pitch English combs, 3-d printed combs, combing with clamped combs, combing with unclamped combs, combing with a hackle, dizzing, and planking! It’s a long episode so set aside some time, get out whatever combs you have (or some fiber and a wheel/spindle) and enjoy! If you don’t have combs, don’t worry, the next episode is all about creating worsted preparations without combs!

We’ll see you again with a new episode in six weeks (but in the meantime, come see us in a spin-in)! If you haven’t already gotten your membership, this is an episode you won’t want to miss!

Join the PLY Spinners Guild here

If you’d like to learn more from your favorite fiber instructors, make sure your membership is active! Each month is jam packed with new instructional videos and virtual spin-ins. Membership is cumulative, meaning you get access not only to the current episode, but also to every previous episode and recorded spin-in as well.

The PLY Spinners Guild (PSG) hosts three 90 minute spin-ins every month:

- On the first Sunday of every month, guild members meet and spin at 5 p.m. Pacific.

- On the third Sunday of every month, guild members meet and spin at 10 a.m. Pacific.

- On the third Thursday of every month, guild members meet and spin at 5 p.m. Pacific. (This is the Building Skills Spin-in for spinners who want a less technical experience than our other spin-ins!)

The guild is priced at $85/year or $12/month. This is a very good deal for the amount of information and community you will get, especially since new video lessons are added every six weeks! This fee allows us to pay for the substantial hosting required by so many high-def videos and the charge per member to access the site, along with fairly compensating the teachers, editors, and everyone involved in making the guild work.

If you aren’t already a member, we think you’d definitely enjoy it!

The PLY Spinners Guild is a space for spinners at all levels of spinning. We are an inclusive and diverse community that embraces all spinners and welcomes everyone to create a brave space to question, challenge, and support one another. We strongly believe that the more diverse our community is, the stronger our community is. Our core beliefs of kindness, diversity, and inclusivity inform everything we do. Racism, sexism, and other forms of oppression will not be tolerated. We reserve the right to remove anyone who meaningfully and purposefully disrupts the community or makes other members feel unsafe.