Today Christina Pappas returns to the blog to walk us through the process of replicating a 2000-year-old slipper!

Today we are going to focus on getting to know the slippers for this project. (Have a look at my post from last week to learn more about my replication project.)

Footwear from 2,000 years ago is really different from what most of us wear today. Going barefoot was probably not uncommon, but there were times when you wanted something on your feet. For example, imagine exploring a cave barefoot. How far could you walk barefoot? Probably not very far. Mammoth Cave in Kentucky is the longest cave system in the world (over 400 miles and counting!) and ancient peoples had explored much of it thousands of years ago. We know they wore slippers because we have found slipper fragments inside the cave.

Footwear from 2,000 years ago is really different from what most of us wear today. Going barefoot was probably not uncommon, but there were times when you wanted something on your feet. For example, imagine exploring a cave barefoot. How far could you walk barefoot? Probably not very far. Mammoth Cave in Kentucky is the longest cave system in the world (over 400 miles and counting!) and ancient peoples had explored much of it thousands of years ago. We know they wore slippers because we have found slipper fragments inside the cave.

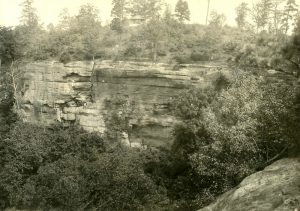

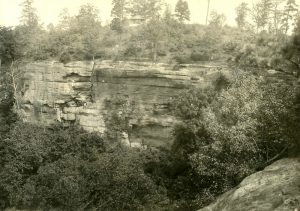

Several of the slippers were excavated from rockshelters in the 1920s and 1930s as a part of the Works Progress Administration (WPA). These images are from a rockshelter in Lee County in Kentucky that produced three of the slippers. Images courtesy the William S. Webb Museum of Anthropology, University of Kentucky.

Several of the slippers were excavated from rockshelters in the 1920s and 1930s as a part of the Works Progress Administration (WPA). These images are from a rockshelter in Lee County in Kentucky that produced three of the slippers. Images courtesy the William S. Webb Museum of Anthropology, University of Kentucky.

We also find fragments of slippers in dry rockshelters. Rockshelters are places along rock walls where you can find shelter from the elements – the kind of place you would rest while hiking to get out of the rain. Kentucky has many rockshelters that are dry, and archaeologists have been able to recover perishable artifacts, including slippers, from these kinds of sites.

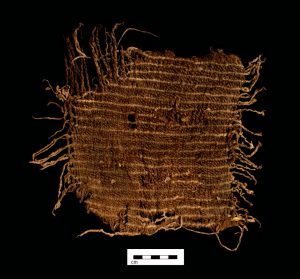

A twined slipper from a rockshelter in Kentucky.

For the slippers we’re going to make, we have to look at several examples to piece together all the necessary traits. All the slippers we’ll be looking at are in the collection of the William S. Webb Museum of Anthropology at the University of Kentucky. They are all from archaeological sites in Kentucky, and most from rockshelters. Only a couple of have been radiocarbon dated directly, but all are approximately 2,000 years old (give or take a few hundred years).

All the slippers are made from plant materials. I can see that the fibers are long, and there is a bit of the outer stem left on some fibers. That tells me that these fibers were not subjected to a lot of processing and appear to be bast fibers. Unfortunately, I can’t completely determine what plant fiber was used; I would need to cut samples and examine them with a microscope to be certain. I do know that these are not from milkweed or nettle fiber, since those fibers are finer than what was used in these slippers. The ancient craftspeople who made these slippers used something woody and hard-wearing, quite possibly fiber from the pawpaw.

A (slightly different) twined slipper from a rockshelter in Kentucky. Image courtesy the William S. Webb Museum of Anthropology, University of Kentucky.

These slippers are all chevron or countered twined. Twining is one of the oldest textile structures with examples dating to over 40,000 years ago in the Old World. In twining, two yarns twist around a third stationary yarn. You can twist every row in the same direction, or you can alternate the direction of each row to create a pattern as was done in our slippers. Twined slippers are made both ways; chevron twining just happens to be my favorite.

The paired yarns that twist are our wefts, and the stationary yarns are our warps. The weft yarns on all our slippers are singles, with a slight Z-twist of 20-30 degrees. The average diameter is about 0.5 cm (about 0.2 inches). The warps are a bit tricky to see and learn about.

A close-up of the heel of a slipper where you can see the plant fibers and the twining structure.

Slippers had to be durable and hard-wearing, so they were twined very tightly and the wefts covered the warps. In the places where the weft has rubbed away, the warp was also damaged and the original yarn structure is not always clear. What I’ve been able to see is that both plied and unplied yarns were used in the warp. A plied yarn was used for the warps near the edge of the slippers, and unplied yarns were used for the warps in the middle. A plied yarn was also used at the toe of the slipper. It functioned like a drawstring to snug the slipper up around your foot.

Using plied yarns makes sense at the edges and as a drawstring – those are the areas where the slipper would take a good amount of abuse and a plied yarn would stand-up better over time. The plied warp yarns are two Z-spun singles S-twisted together, and the unplied warps are Z-spun singles. The warps average about 0.8 cm (about 0.31 inches) in diameter. The plied yarns average about 1.5 twists/cm and the unplied warp yarns average 0.5 twists/cm. I wasn’t able to get a measurement for the twists/cm for the weft yarns. The dense twining made it difficult to get consistent measurements.

A slipper toe where you can see the drawstring. You can find a drawing of a completed slipper here.

So, what have we learned so far?

I know that my slippers will need to be made out of a ‘harder’ bast fiber. Pawpaw was used prehistorically for slippers, and I know a few farmers who still grow them. My fiber will need minimal processing. I will use chevron twining to weave my slippers. My yarn goals are:

- Z-spun single, approximately 0.5 cm thick, 0.5 twists/cm

- Z-spun single, approximately 1.0 cm thick, 0.5 twists/cm

- 2 Z-spun singles S-plied together, approximately 1.0 cm thick, 1.5 twists/cm

I’m going to have to figure out how to process my fiber, how to spin my yarn, and how to weave my slipper. These are all steps that will be based on what I’ve learned from other fiber artists and early historic descriptions of spinning in the Southeast, not on anything we know for sure from the archaeological record. This is where the real trial-and-error begins!

Next time we chat, we’ll get to know the other textiles for this project.

Chris Pappas is an archaeologist by day and a fiber fanatic by night who is happiest when she can be both at the same time. She lives in Kentucky with her husband, adorable baby girl, and two crazy beagles.

Footwear from 2,000 years ago is really different from what most of us wear today. Going barefoot was probably not uncommon, but there were times when you wanted something on your feet. For example, imagine exploring a cave barefoot. How far could you walk barefoot? Probably not very far. Mammoth Cave in Kentucky is the longest cave system in the world (over 400 miles and counting!) and ancient peoples had explored much of it thousands of years ago. We know they wore slippers because we have found slipper fragments inside the cave.

Footwear from 2,000 years ago is really different from what most of us wear today. Going barefoot was probably not uncommon, but there were times when you wanted something on your feet. For example, imagine exploring a cave barefoot. How far could you walk barefoot? Probably not very far. Mammoth Cave in Kentucky is the longest cave system in the world (over 400 miles and counting!) and ancient peoples had explored much of it thousands of years ago. We know they wore slippers because we have found slipper fragments inside the cave. Several of the slippers were excavated from rockshelters in the 1920s and 1930s as a part of the Works Progress Administration (WPA). These images are from a rockshelter in Lee County in Kentucky that produced three of the slippers. Images courtesy the William S. Webb Museum of Anthropology, University of Kentucky.

Several of the slippers were excavated from rockshelters in the 1920s and 1930s as a part of the Works Progress Administration (WPA). These images are from a rockshelter in Lee County in Kentucky that produced three of the slippers. Images courtesy the William S. Webb Museum of Anthropology, University of Kentucky.