Hacking Yarn Tools: How to DIY an Electronic Yarn Meter

photos and words by Carrie Sundra

How much yarn is in this ball? How do I break up a skein into smaller consistent lengths? How can I wind a specific length of yarn off of this cone? Measuring yarn length is a seemingly simple task, until you try to do it, especially if you expect repeatable results. Usually, a ball or skein of yarn will be labeled with yarn length and yarn weight. It stands to reason that you could accurately estimate the length of yarn in a leftover ball by weighing it and calculating length from the original weight/length on the ball. What many people don’t realize is that label markings are very approximate. Weight depends on humidity, so the same skein can weigh different amounts in different locations. Length is also approximate and depends on the amount of tension the yarn is under. Both figures may also be minimum estimates, with the manufacturer/yarn dyer winding off a few extra yards or grams as standard practice.

Another method of measuring yarn length is winding a skein of a certain circumference and counting wraps. This is a pretty typical method used by handspinners – you create a skein with a niddy-noddy or winder, you know the circumference of the skein (typically 1.5–2 yds or meters), and you count the number of loops in the skein. This isn’t a bad method but also depends on tension of the yarn. Also, once the yarn starts wrapping over itself, or depending on the path it takes around a niddy noddy, the circumference will change. It’s still an estimate.

A third way of estimating yarn length is by using the measuring wheel method. In this method, you wrap a piece of yarn once around a wheel and run the entire skein of ball through the wheel, counting the wheel’s rotations. This is similar to the measuring wheels surveyors use, rolling them along the ground to measure distance. The benefit to this method is that the wheel is a fixed diameter, the yarn doesn’t build up on the wheel so the length that the yarn travels is also fixed, and if you wind from a ball to another ball, there’s generally not a lot of tension on your yarn that will stretch it and heavily skew the results (unlike using a skein winder and swift, where there tends to be more tension from the yarn wrapping around the winder and pulling at the swift). It does depend on the yarn dragging the wheel around as it travels, so it does require a certain amount of friction. Very slippery yarns like 100% silk or nylon may lessen the accuracy. Generally, a larger wheel reduces slippage and undergoes fewer rotations so that some errors don’t add up as much. However, for hacking purposes, I thought using a common household item was easier than constructing a custom device, so I tried out a tape dispenser and had surprisingly good results.

The key takeaway is that any talk of accuracy implies that there is some “truth” against which deviations are measured. With yarn length, there is no real “truth” because length changes with tension, so it’s all an estimate!

Building your own electronic yarn meter

Here’s how you can build your own measuring-wheel-style electronic yarn meter. You can also find these instructions on our Hackaday.io page.

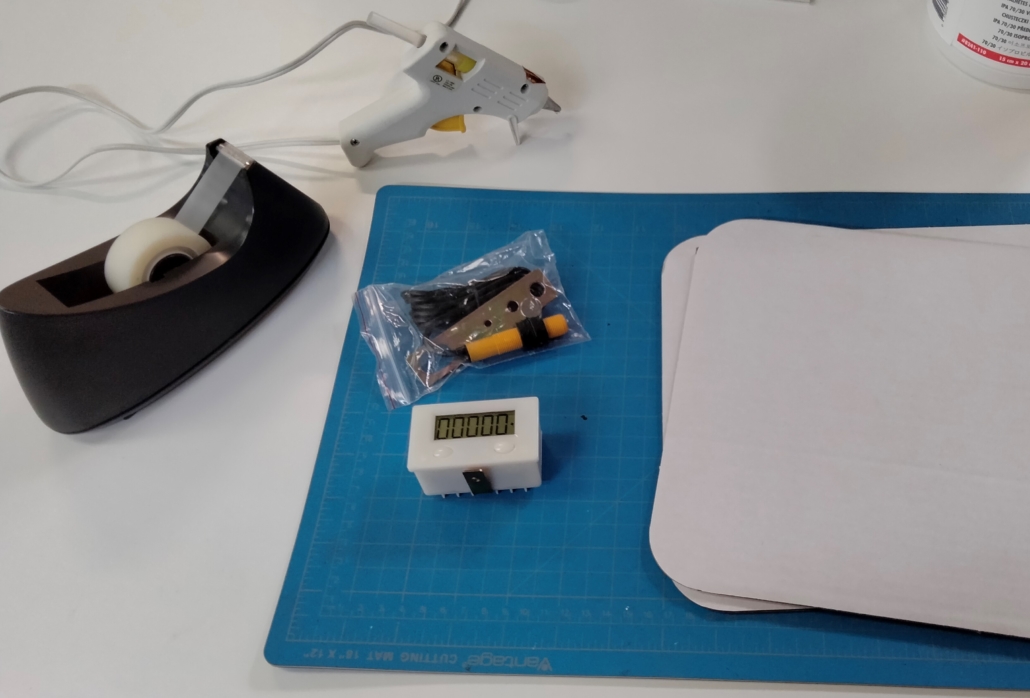

Step 1: Gather your tools

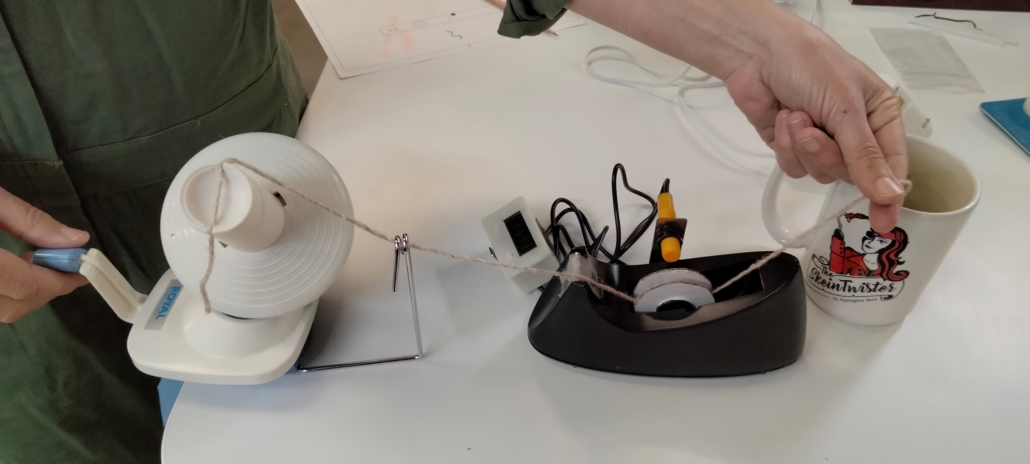

You’ll need:

- A weighted tape dispenser with 1-inch core, similar to this one.

- A full roll of tape

- A digital magnetic counter kit

- Cardboard

- A pen or pencil

- Scissors or an exacto knife

- Phillips/plus-tip screwdriver

- Pliers

- Hot glue

- A hand crank ball winder, like this one.

- A ball of yarn

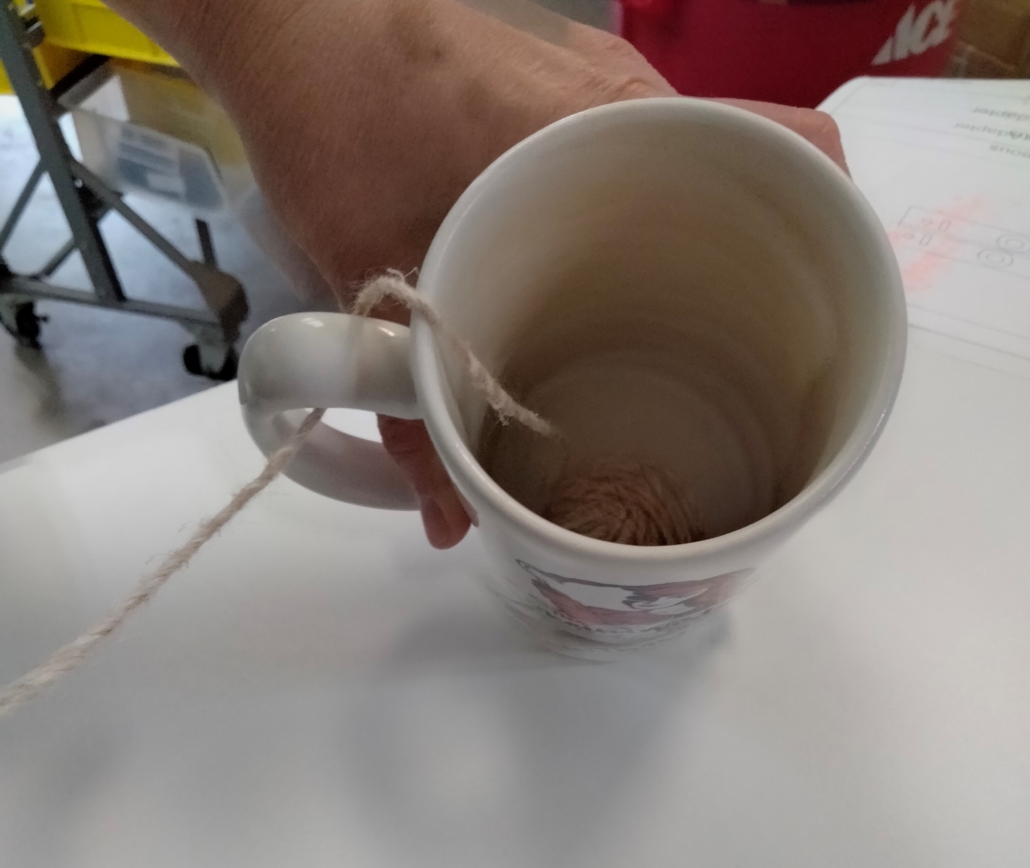

- A smooth container or yarn bowl for containing yarn as it unwinds

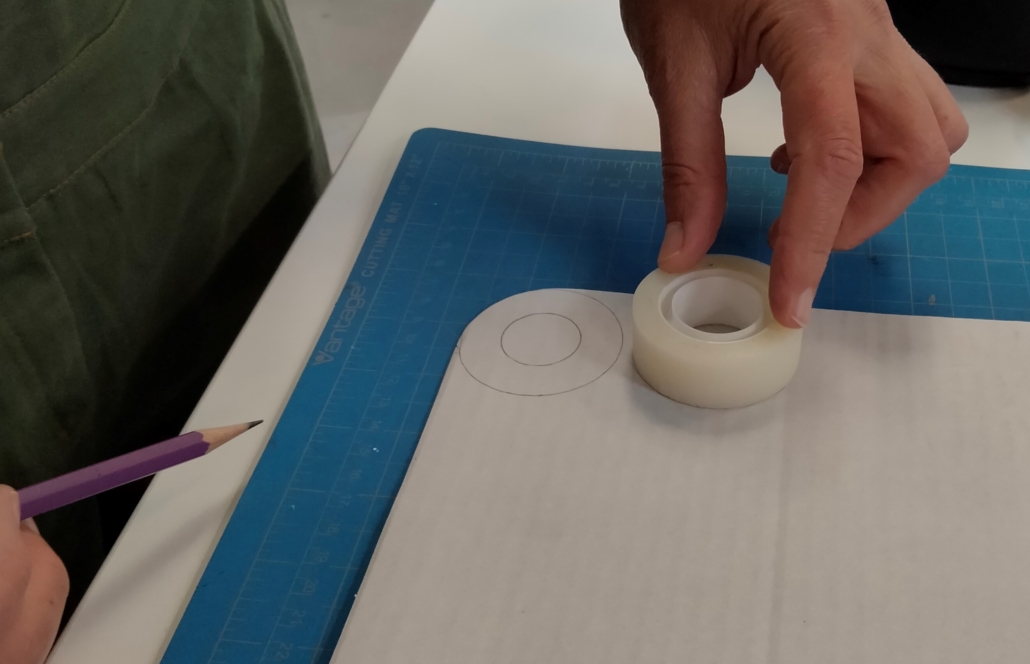

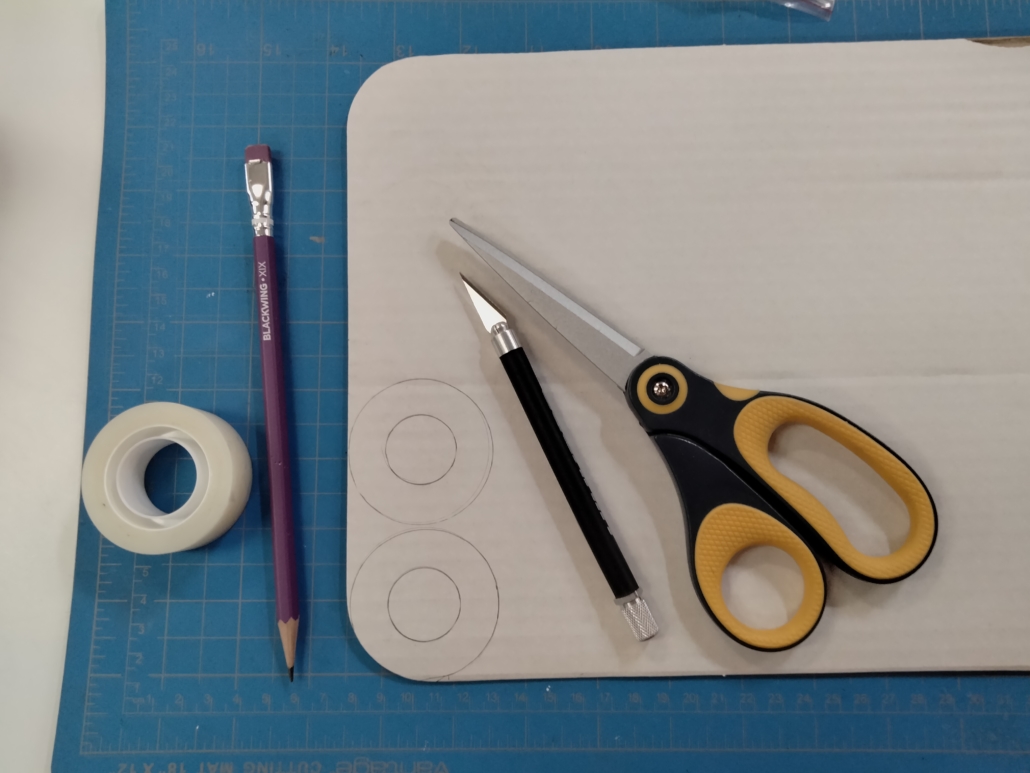

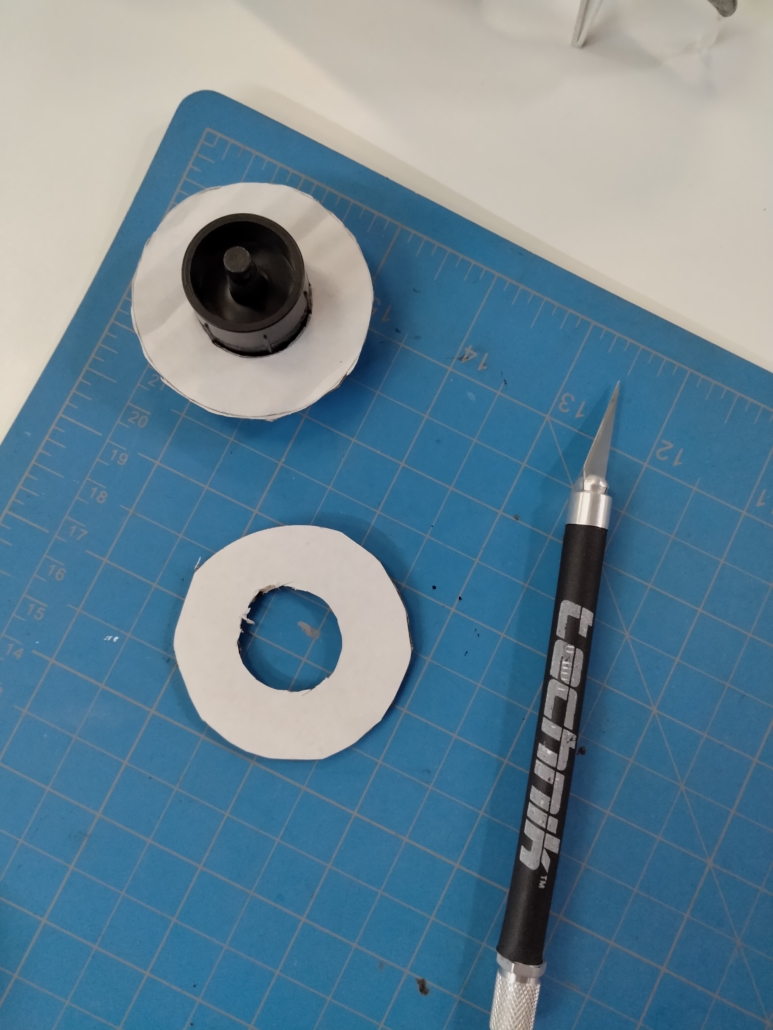

Step 2: Cut your yarn guides

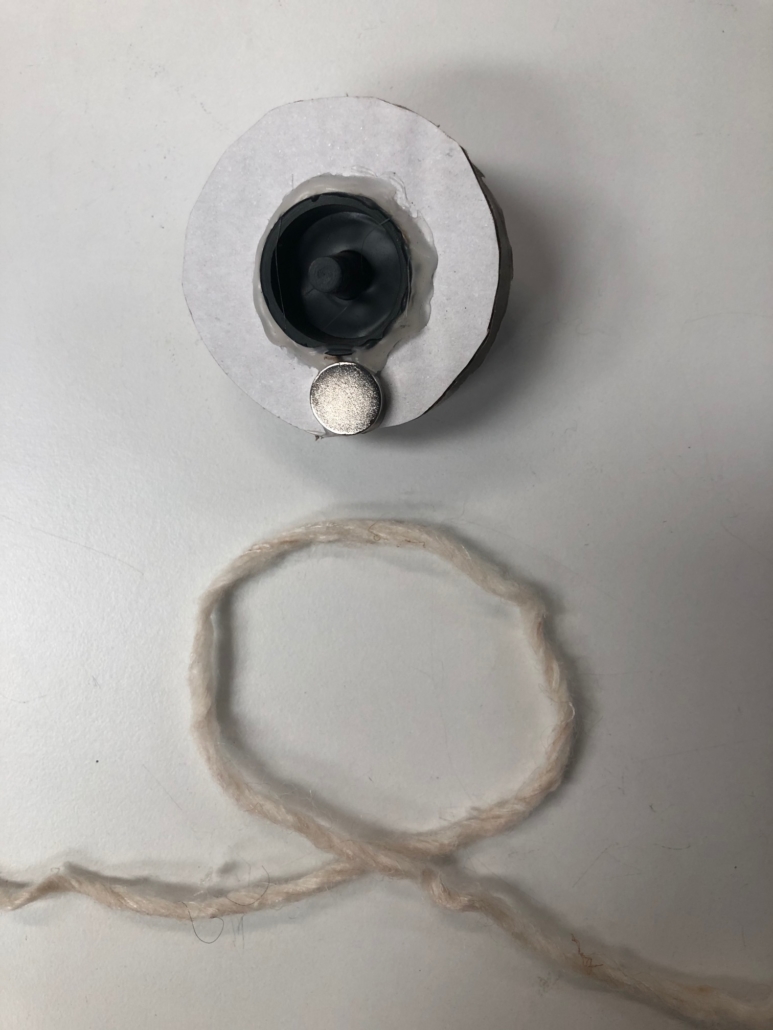

Take the roll of tape and trace the inside and outside of the roll. Make two donuts. Cut them out with scissors or an exacto knife.

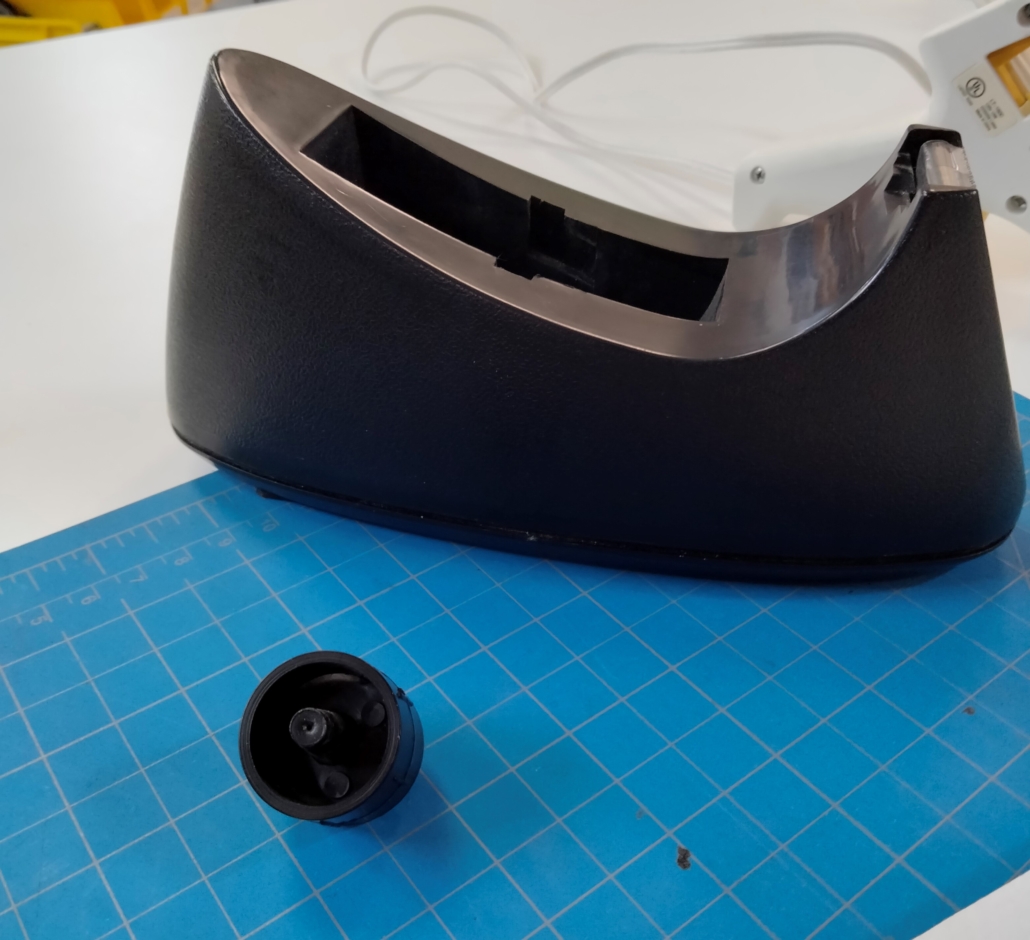

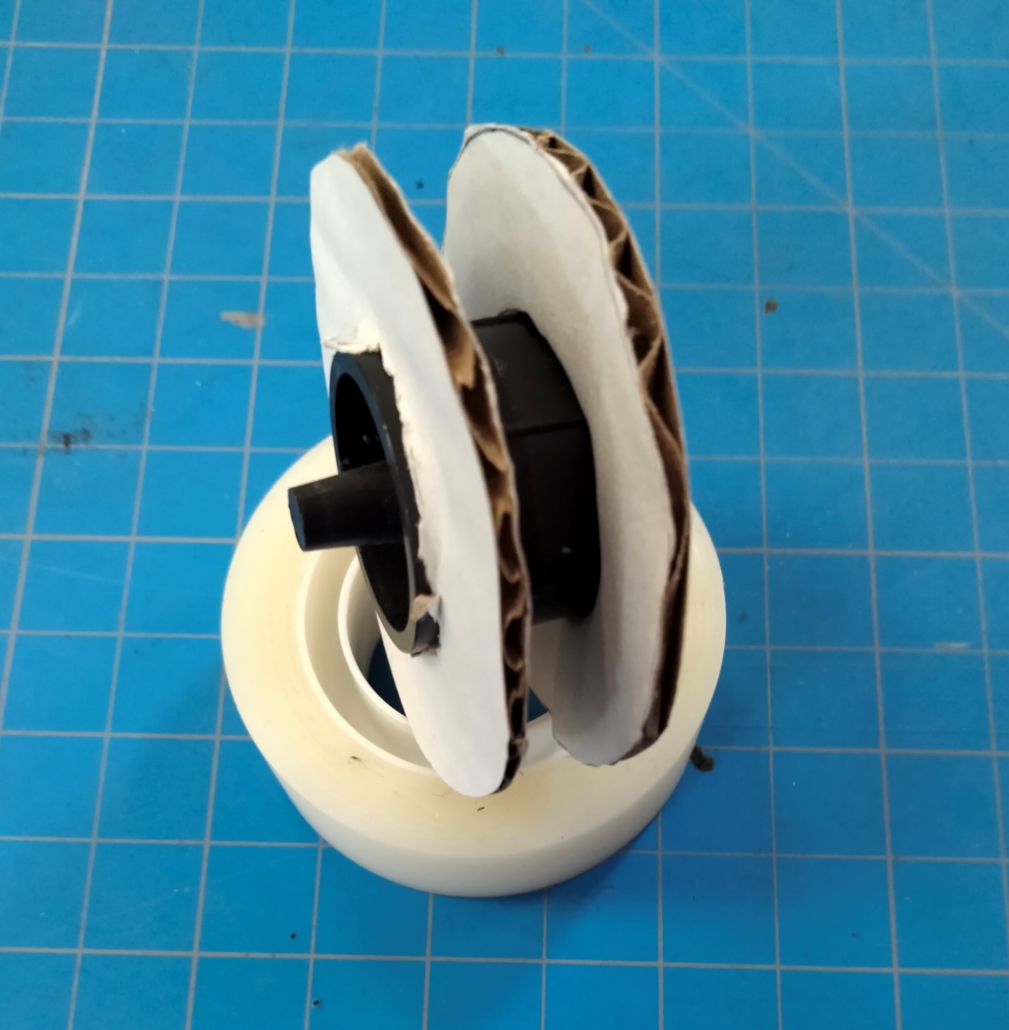

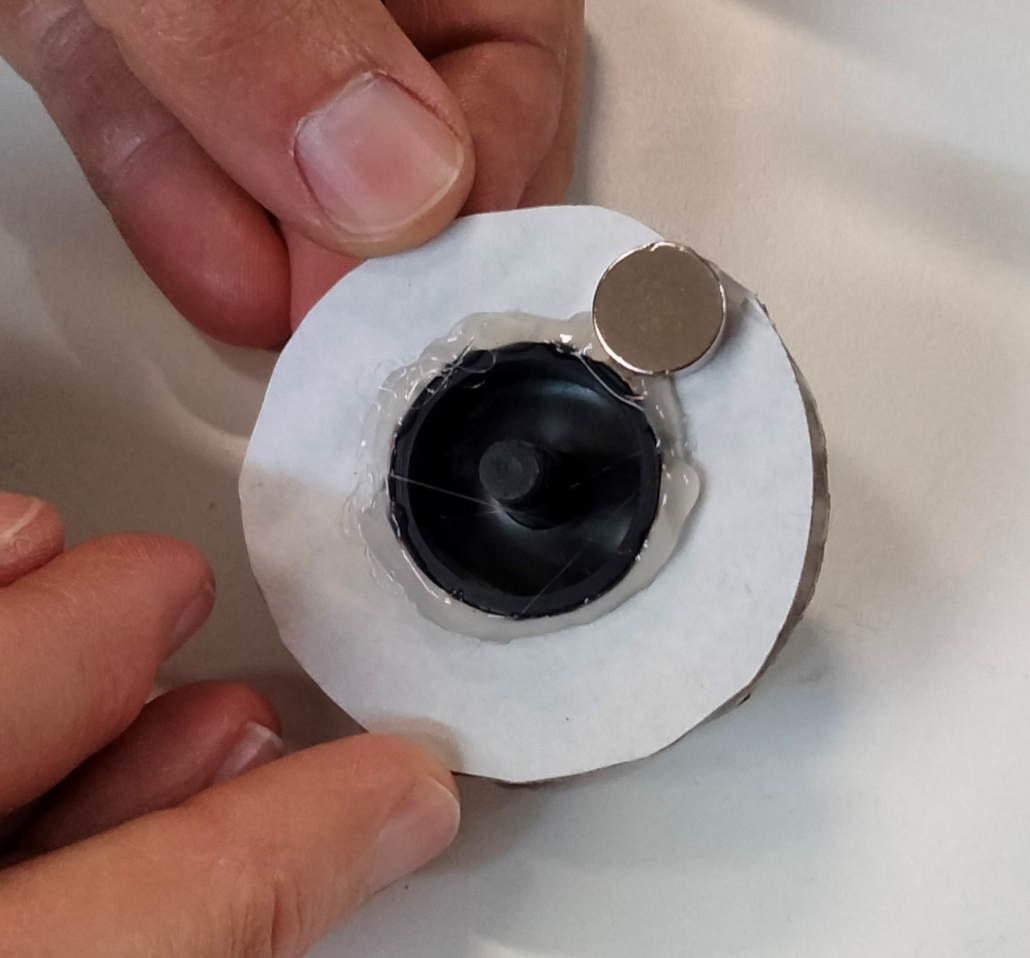

Step 3: Attach the yarn guides & magnet

Take your yarn guides and push them onto either end of the core of your tape dispenser. They may stay put as-is, but ours loosened and flopped after winding a few balls, so we recommend hot-gluing them in place. Also hot-glue the magnet to the outside of one of the yarn guides. Note: We have an older-style tape dispenser with a round core. If yours has a triangular core, that’s okay too.

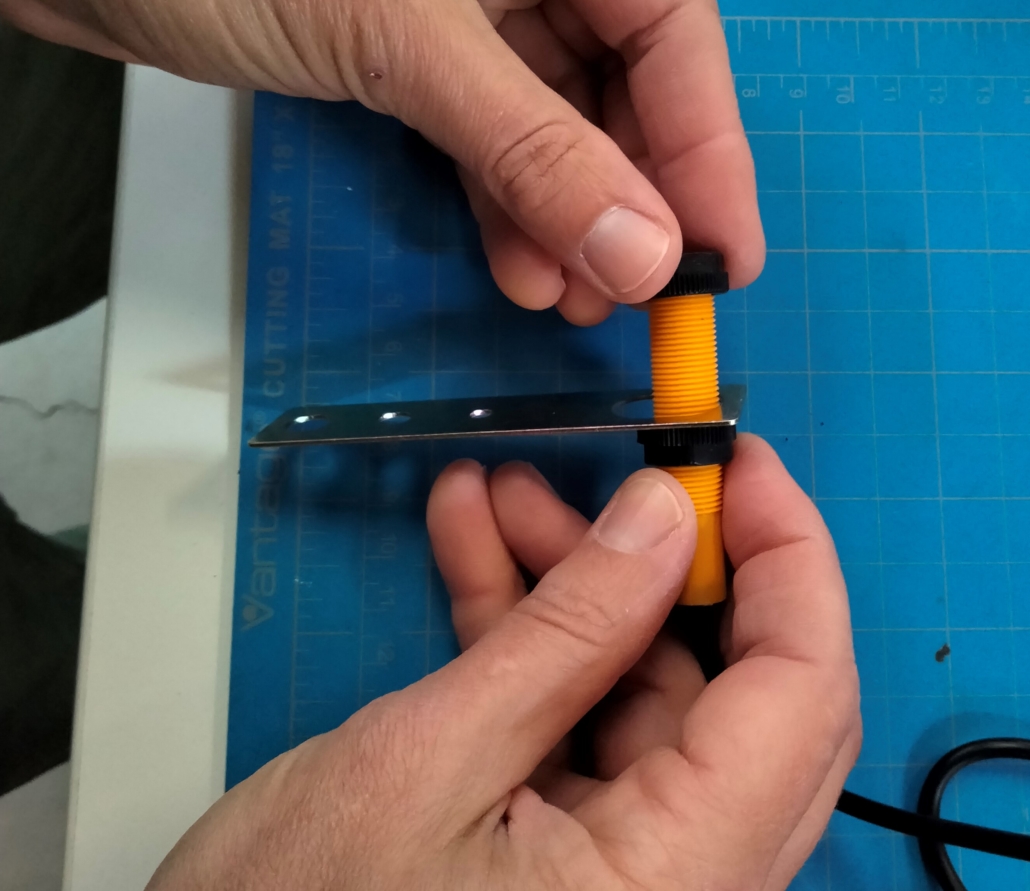

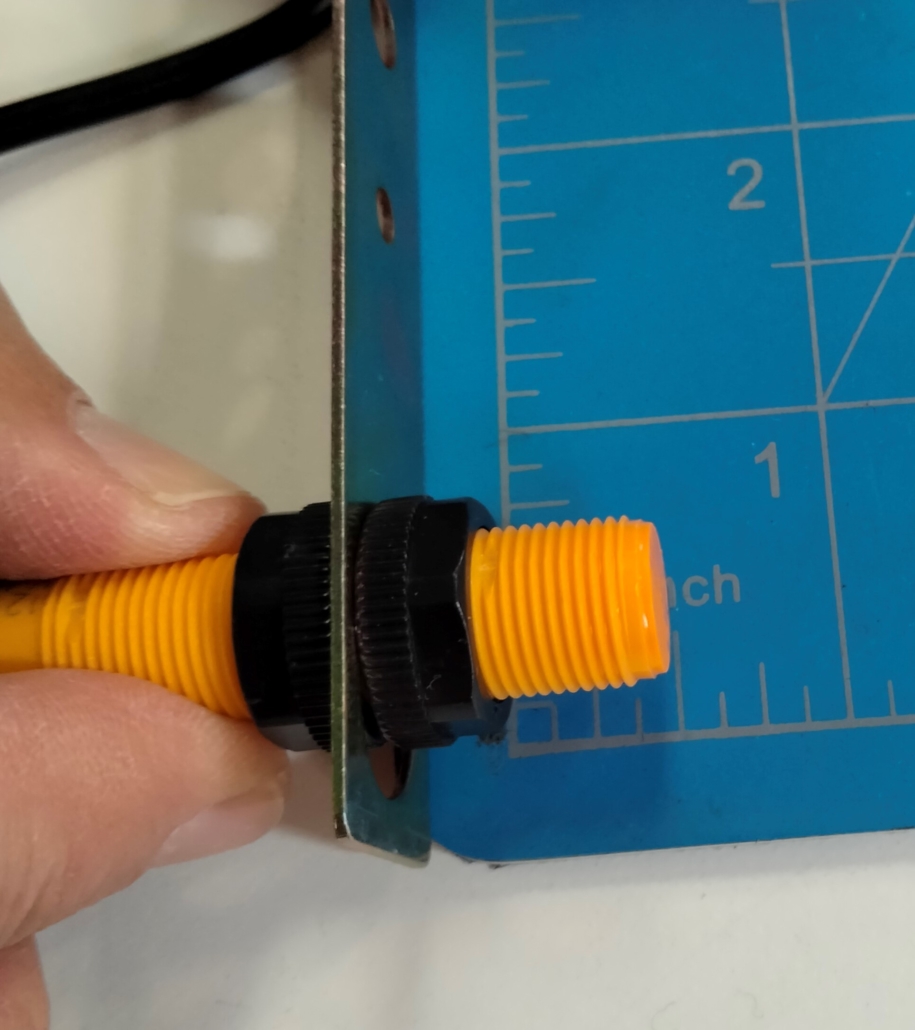

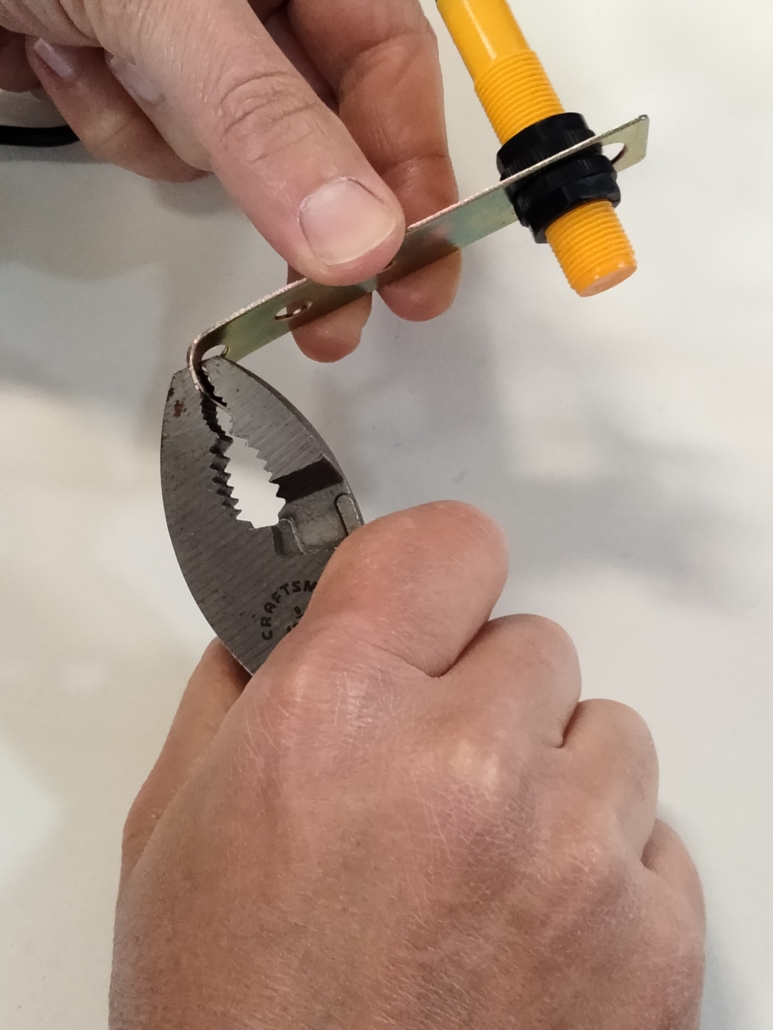

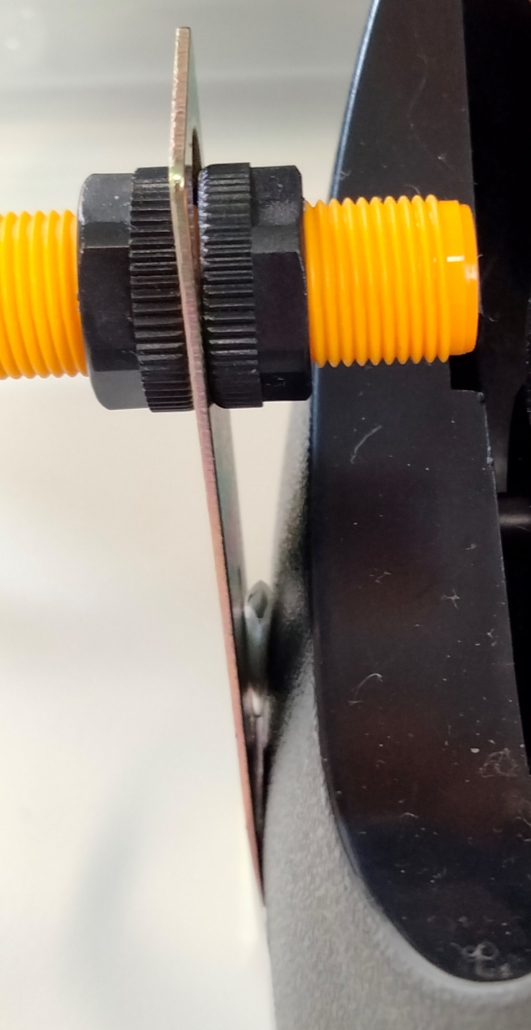

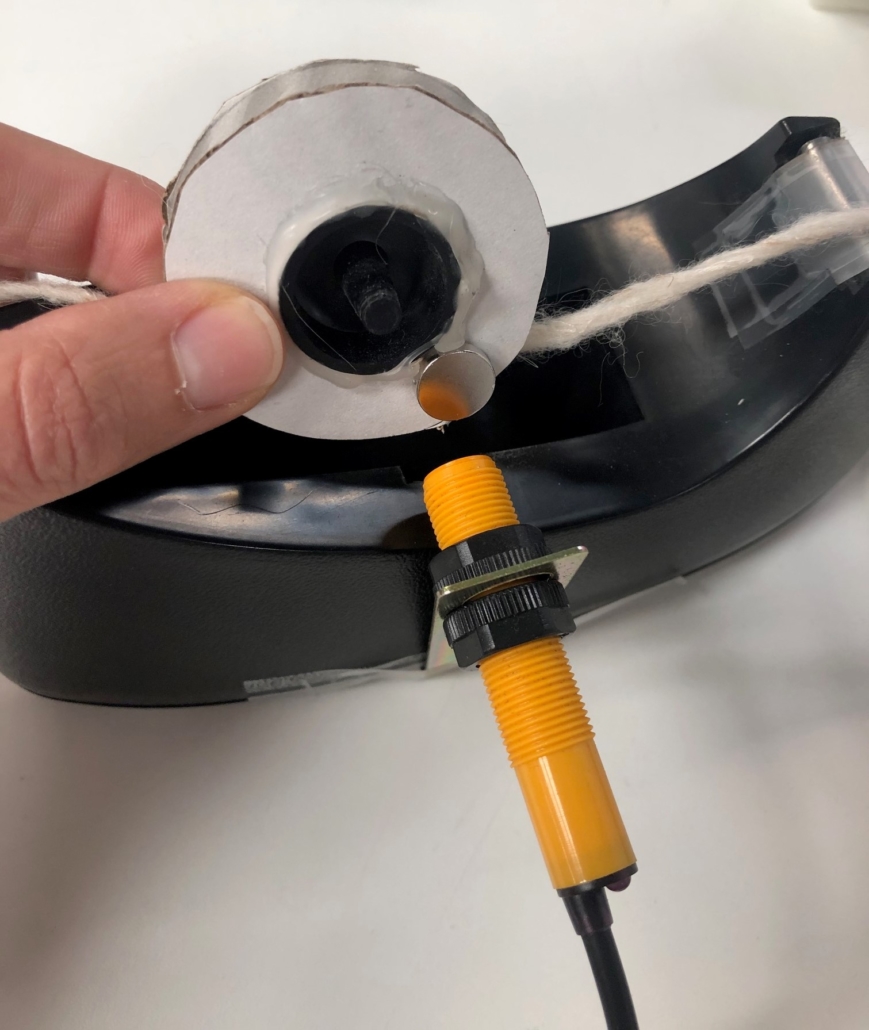

Step 4: Prepare the rotation counter

Unscrew one of the nuts on the rotation counter, push the rotation counter through the large oblong hole on the mounting bracket that comes with the kit. Adjust both nuts so there’s about 3/4 inch (19 mm) from the end of the tip of the counter to the mounting bracket. Using pliers, bend the other end of the bracket into an “L”, about midway through the bottom hole on the bracket. (Note: Read through the next step as well; the amount of L or where you bend the bracket may need to be different for your particular tape dispenser.) The tip of the L should be on the same side as the tip of the rotation counter.

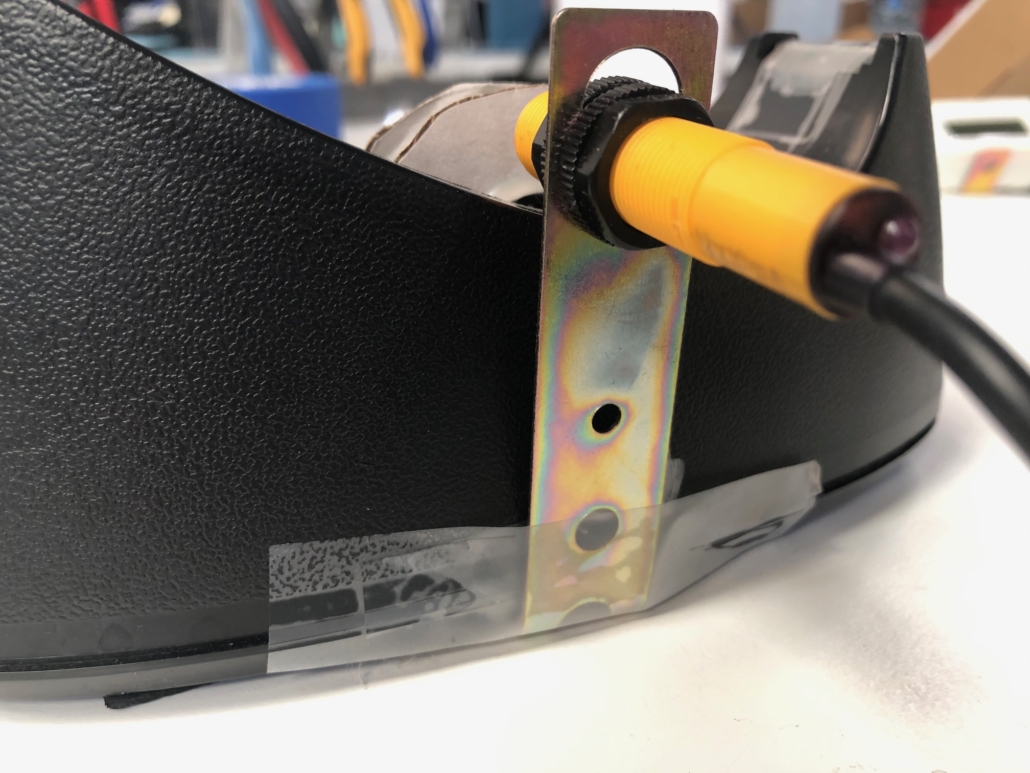

Step 5: Assemble the rotation counter and magnet

Place the tape dispenser core with yarn guides back into the tape dispenser. Rotate the core so the magnet is at the top; you’ll need to hold it there with one hand. With your other hand, hold up the rotation counter bracket on the side of your tape dispenser. The magnet and the rotation counter tip should be directly opposite each other, with approximately a 1/8-inch (3-mm) gap between them. If the gap is different, adjust the nuts on the rotation counter. If the rotation counter is more than 1/8 inch above or below the magnet, adjust the place where you’ve bent the bracket.

Step 6: Tape the bracket to the dispenser

Use a few pieces of tape to attach the bracket to the dispenser. The bracket should be as close to vertical as possible. Our tape dispenser had slanted sides, so we folded up a piece of tape and stuck it between the bracket and tape dispenser to hold it in a vertical position. This helps with consistent spacing between the magnet and counter, which helps with consistent counting! At this time, also use a few pieces of tape to tape over the serrated edge of your tape dispenser. We don’t want it roughing up your yarn!

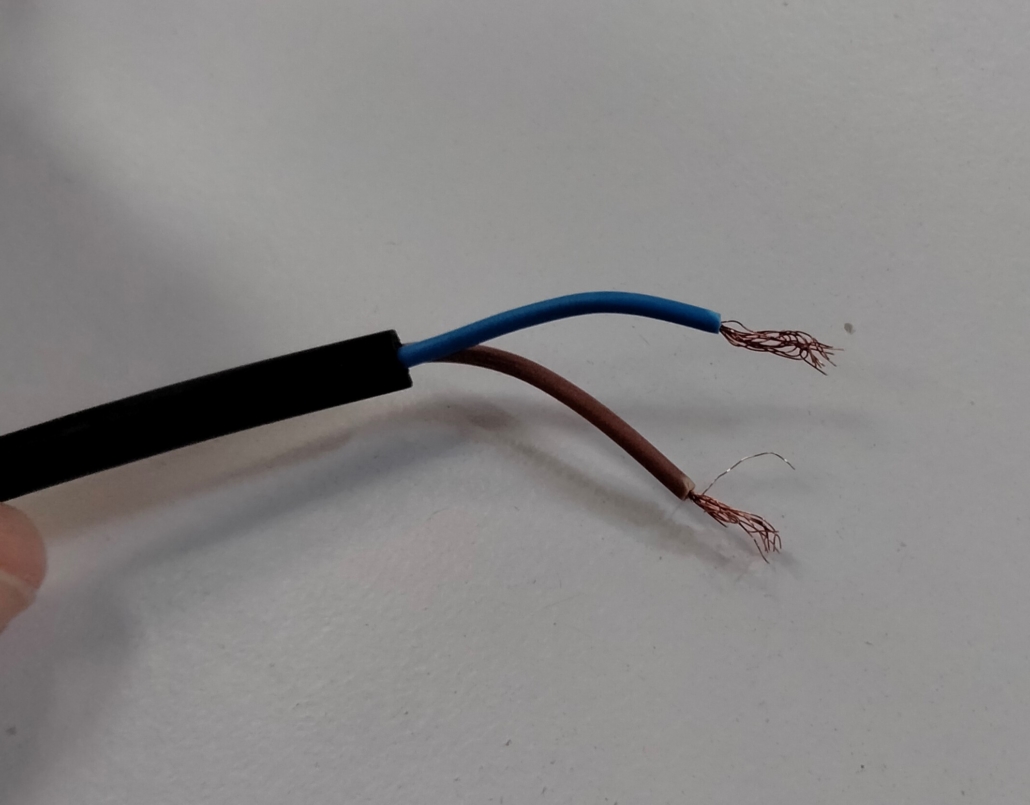

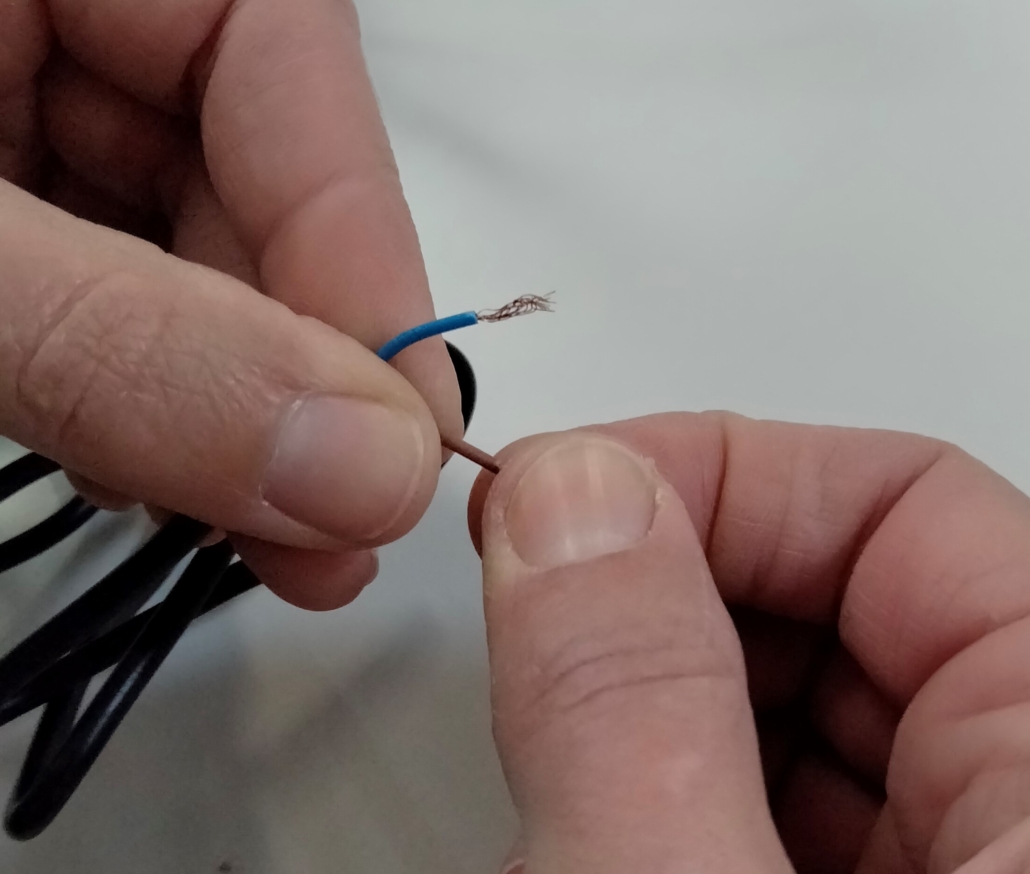

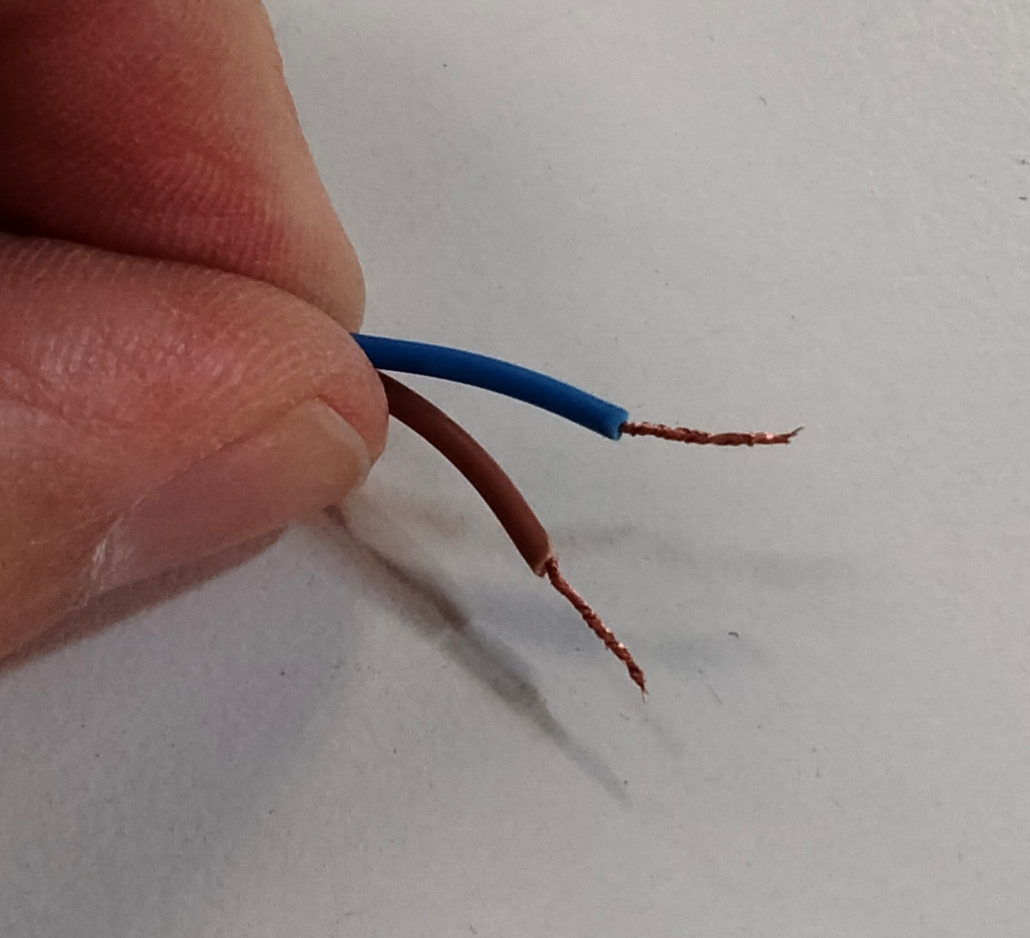

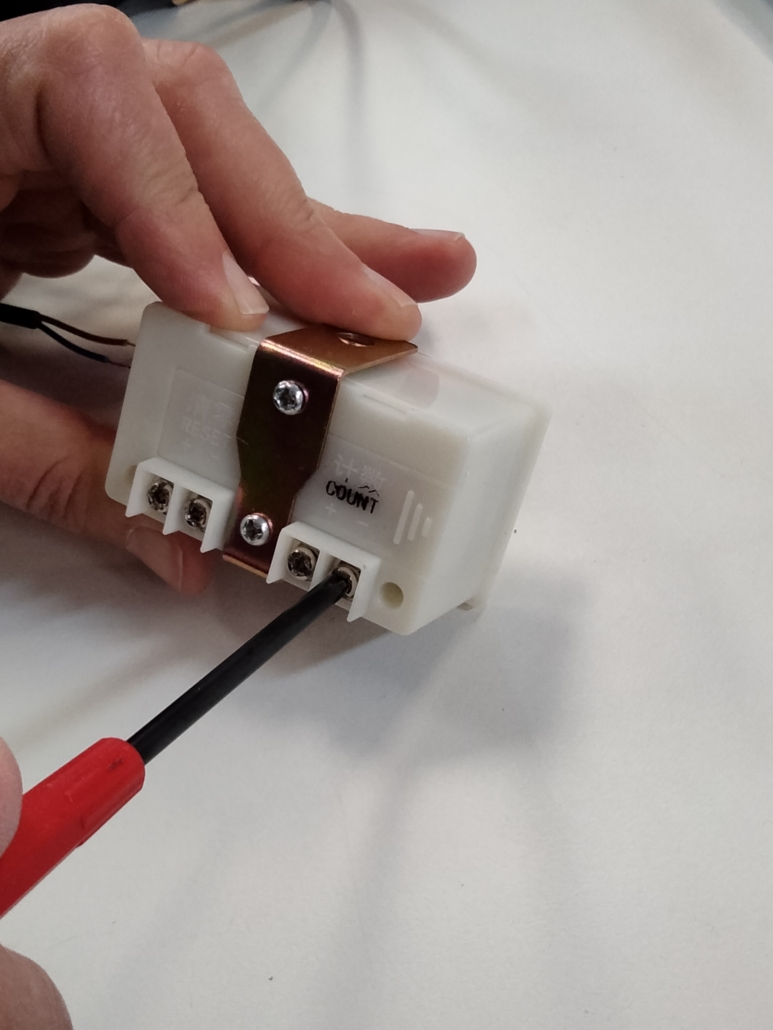

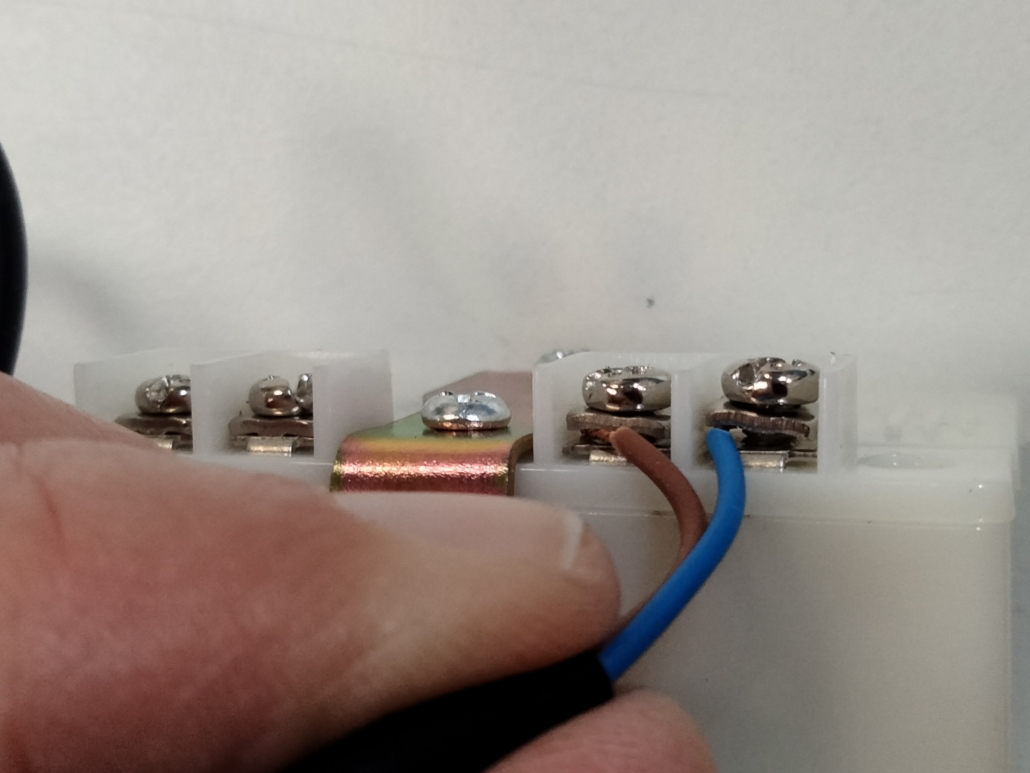

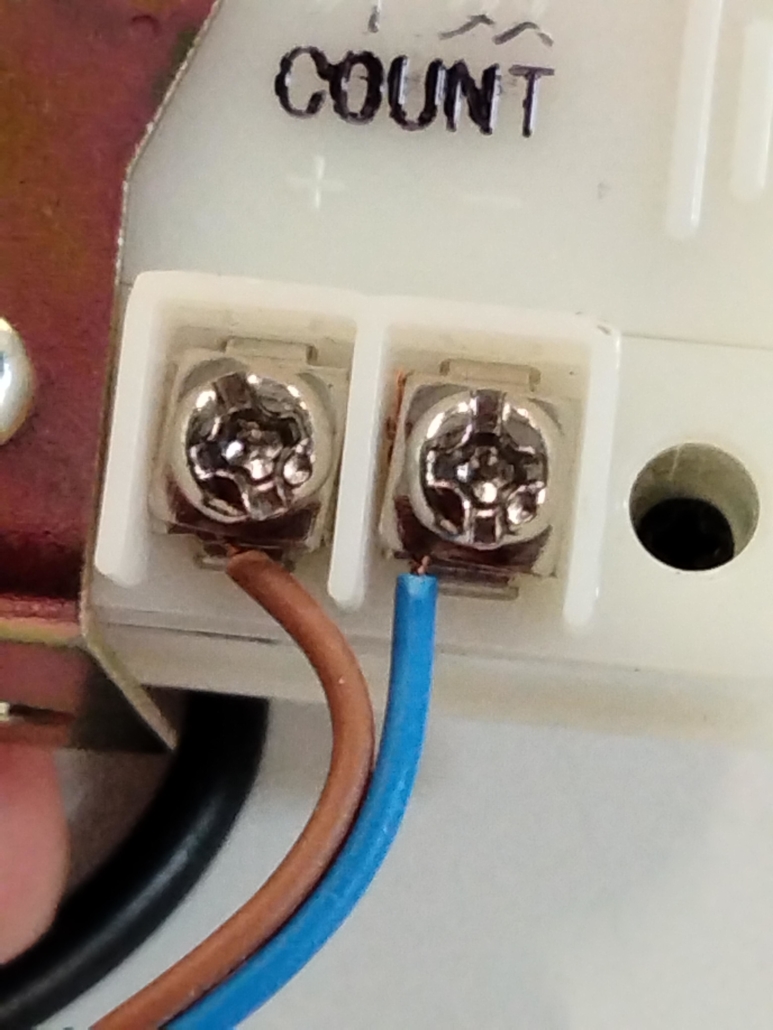

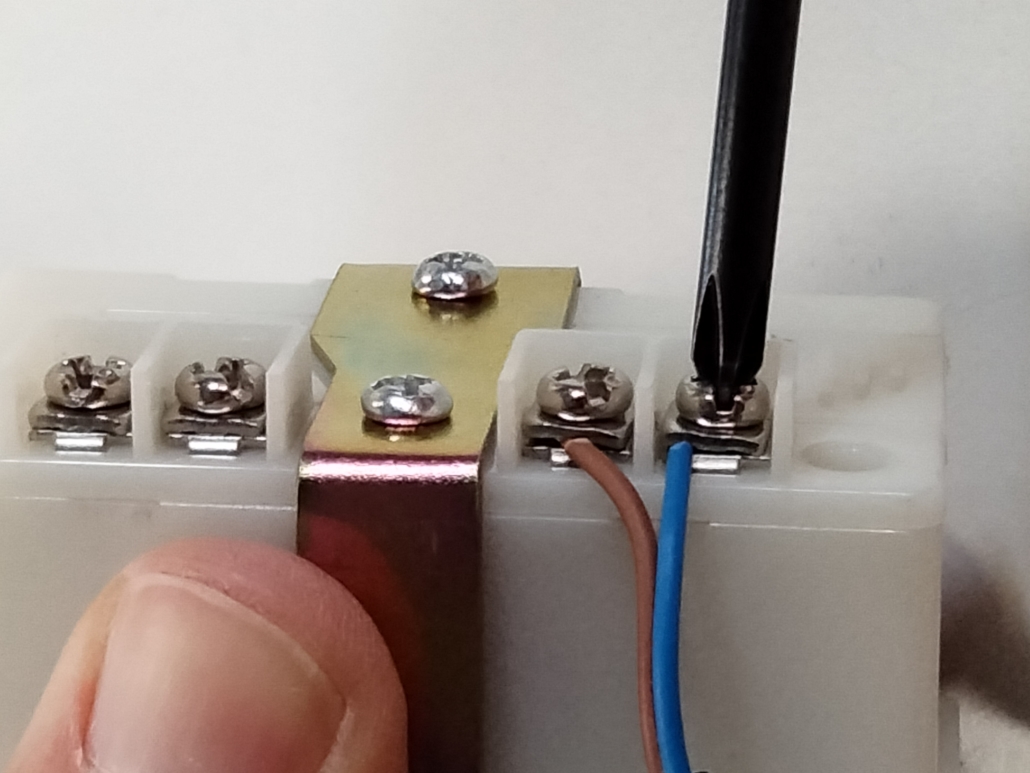

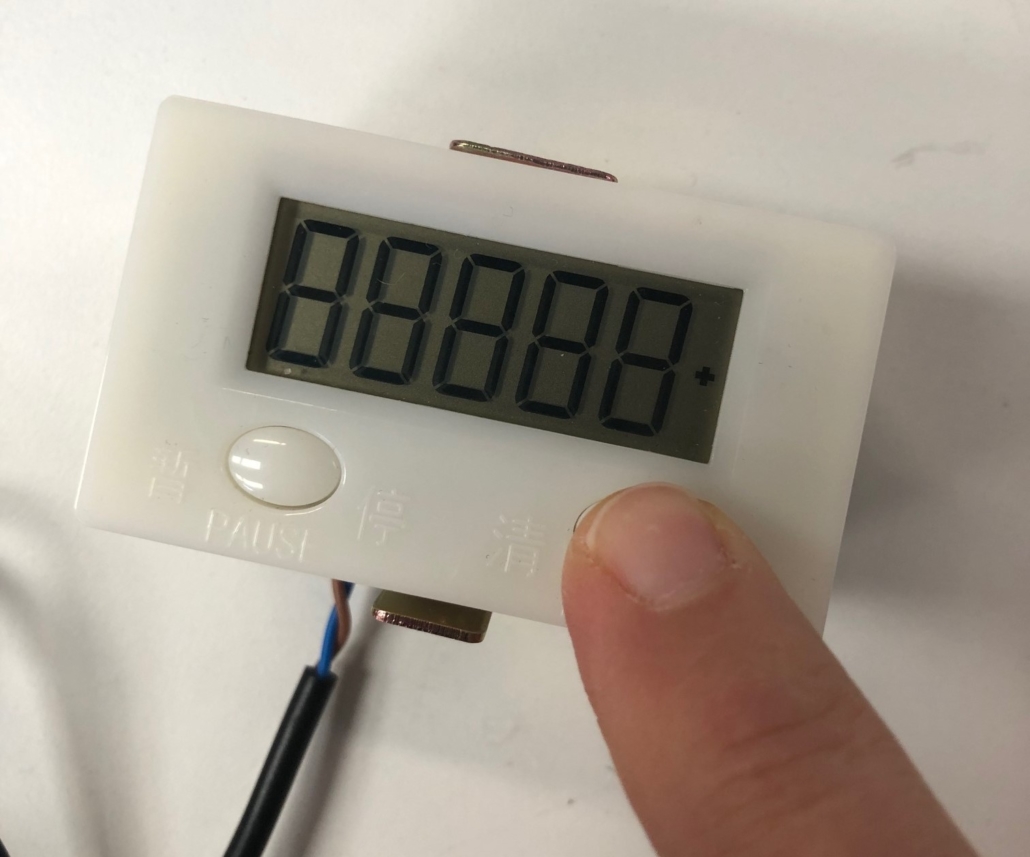

Step 7: Attach the rotation counter to the display

The rotation counter should already have stripped wires, meaning some copper strands are exposed from the insulation, but the strands might be a little frayed. Using your fingers, twist each of the wire ends together so they’re nice and tidy. The LCD should by default have a battery installed and be displaying all zeros in black. If the display is completely blank, unscrew the bracket and back compartment, insert a new battery, and screw it back together. With the Phillips screwdriver, unscrew each “COUNTER” terminal on the LCD display a few rotations so they’re loose but still screwed in a little. The word “COUNTER” is embossed in the white plastic and may be difficult to see; we’ve used a marker to make it black in the photo. Insert the wires between the two plates in each terminal. It doesn’t matter which wire is on the left or right. Screw the terminals back down tightly so the wires are firmly sandwiched between the plates. Set the LCD next to the tape dispenser.

Step 8: Test your counter

Manually rotate the tape dispenser core around a few times, passing the magnet by the tip of the rotation counter. With each pass, the display on the LCD should count up! Note that there’s no way for it to tell direction – it will count up by one no matter which way you turn the core. Press the Reset button to zero the count. We don’t use the pause button; note that if you press it, the counter will no longer count up.

Step 9: Set up your winding

Yay, you’re ready to test it out with some yarn! Clamp your ball winder to a surface, like you would for winding any ball of yarn. Set the tape dispenser in front of the yarn guide so the taped-over serrated edge is opposite your yarn guide. Place the LCD someplace you can see it while winding. Place the yarn container (or yarn bowl) in back of the tape dispenser so all 3 parts are in a line. Take the core out of your tape dispenser. Take an end of your yarn from the ball (if you have an inside vs outside choice, we tend to prefer inside. If the inside is trapped, outside is totally fine), and loop it around the core once, leaving about a one-foot (30-cm) tail. Direction of the loop doesn’t matter. Place the core back inside the tape dispenser, making sure the yarn is within the two yarn guides. Run the end of the yarn through your ball winder’s yarn guide, and attach it to your winder core.

Step 10: Wind and count!

Make sure your yarn is between the yarn guides in the tape dispenser. Zero the count on the LCD display. You will need to guide the yarn properly with your non-winding hand so the core doesn’t jump out of the tape dispenser. Take a loop of yarn from the ball side, and bring it toward you and above the ball winder. Between this and the pull from the ball winder, you should be able to keep a little bit of tension on the tape dispenser core, pulling it toward you, which keeps it seated. We found that pulling the yarn all the way to you and holding it directly above the ball winder was comfortable and worked well. Start winding away! You’ll get approximately 8 rotation counts per crank of the ball winder. Keep winding slow and steady so the core doesn’t jump and so you don’t get going so fast you miss counts. This didn’t happen to us but could theoretically happen. Keep cranking at about 1 to 1.5 cranks per second. When your run out of yarn, since the core is weighted, it will stop. It won’t freespin and add extraneous counts. Check out our video of this step:

Step 11: Do the math!

Now on your LCD, you have a display of number of tape core rotations undergone while winding this ball of yarn. Now let’s turn that into a measurement of length! Tape cores are generally a standard 1 inch (25.4 mm) in diameter in the U.S. We need the circumference to figure out how much yarn goes around with each rotation. Easy-peasy – circumference is just diameter x pi. So 1 inch x 3.14 = 3.14 inches (7.98 cm) of yarn per rotation. There are 36 inches per yard (or 100 cm per meter). So multiply your number of rotations by 3.14 and then divide by 36 to get yards. Or multiply rotations by 7.98 and then divide by 100 to get meters.

But what if you have a triangular-shaped core? You can take a piece of yarn, wrap it around the core, mark the beginning and end of the wrap, then unwrap it and measure the distance between beginning and end. This is your equivalent circumference. Multiply it by the number of rotations to get total length. If you measured in inches, divide by 36 to get yards, or if you measured in cm, divide by 100 to get meters. Our triangular core’s equivalent circumference was about 3 inches.

We’ve already talked about how it’s difficult to speak of “accuracy” and measuring yarn length because there are so many variables and conditions. There will be a little bit of yarn consumed in the measuring wheel setup that won’t be accounted for, and the last bit that comes off the counter at the end may not cause the core to rotate. This won’t add up to be more than 1 yd. We’ve talked about yarn tension, and consistent length measurement will depend on consistent yarn tension throughout the winding, regardless of how much the ball is flopping around. We also mentioned fiber content and slipperiness; stickier yarn like non-superwash wool won’t slip on the core while 100% silk or nylon might. Speaking of the core, if it’s a little bigger or smaller than the standard 1-inch diameter, that could account for some error, and you may want to plug in the actual diameter of the core into the calculations above. Your speed and whether you have to start and stop to fix snags may also introduce some error.

Even with all of these variables, we can get an idea of measurement repeatability by winding the same ball over and over again. We found that if you’re an experienced yarn handler who is able to quickly and automatically adjust your fingers to keep consistent tension while winding, you can achieve very repeatable results, within 3–5% over multiple windings of the same ball. If you’re not as experienced with yarn management, then it’s closer to 10%. So if you want to be conservative in your length estimation, estimate that the minimum length of yarn in your ball is 10% less than your calculation. Happy yarn length estimating!

Carrie Sundra is an engineer with a serious yarn addiction, who decided to leave a life of electronics and high-tech spy planes for hand-dyeing and knitting. Alpenglow Yarn started in 2009 with 3 words: Glowing Natural Color. Her most well-known products, the SkeinMinder and SkeinTwister, add automation to winding and twisting operations, make the process more efficient, and help scale up production. You can find out more at alpenglowyarn.com.

Did you know we also have a monthly PLY newsletter? Sign up here!

PLY Magazine believes that Black lives matter, as well as LBGTQI+ lives. Those most vulnerable and persecuted in our communities deserve our love and support. Please be good to each other.

Oh my! I got so excited, but by the time I got just barely a third of the way through the directions, I was totally lost! Will have to wait until someday I can snag someone who was successful at this and have them help me understand the assembly! But thanks for sharing! Perhaps accurate measurements await me in the future! 🙂

Sometimes in cases like that when i can’t mentally follow the directions, i can be successful by physically doing it. Try getting the supplies and walking through it. For example i simply can picture turning a sock heel. i literally have to follow the directions step by step every.darned.time.but it works!