Warm West Coast Wool: Salish style

words and photos by Liz Hammond-Kaarremaa

Cowichan sweaters are famous throughout the world for being thick, light, warm, and cosy. The yarns demonstrate ancient expertise with spinning warm yarns. The Cowichan (now known as Quw’utsun) First Nations of Vancouver Island on the west coast of Canada are part of the Coast Salish language family of nations surrounding the Salish Sea and Puget Sound. They, along with their neighbours, have been spinning warm yarns for thousands of years, yet sheep only arrived in the area in the mid-1850s. So how did they learn to spin such warm fibres in a land where animal fibres are rare? And what can they teach us about spinning warm yarns?

From spindle to treadle machine

Originally the Coast Salish spun dog wool (see my article, “The Coast Salish Woolly Dog,” in the Spring 2020 issue of PLY) and mountain goat wool, sometimes mixed, sometimes alone. First, they slightly twisted fibres on their thigh into a rough roving which they then wound into balls in preparation for spinning on a spindle. The unique spindle is long at 36 inches, similar to a Navajo spindle but with a very large whorl (6–10 inches), and is spun by rolling the spindle down the thigh or lifting it in the air above the laps to twirl it. This provided a lofty thick yarn which traditionally was plied and woven into blankets. The Coast Salish adapted their unique spindle to spin sheep wool once sheep arrived in the mid 1800s.

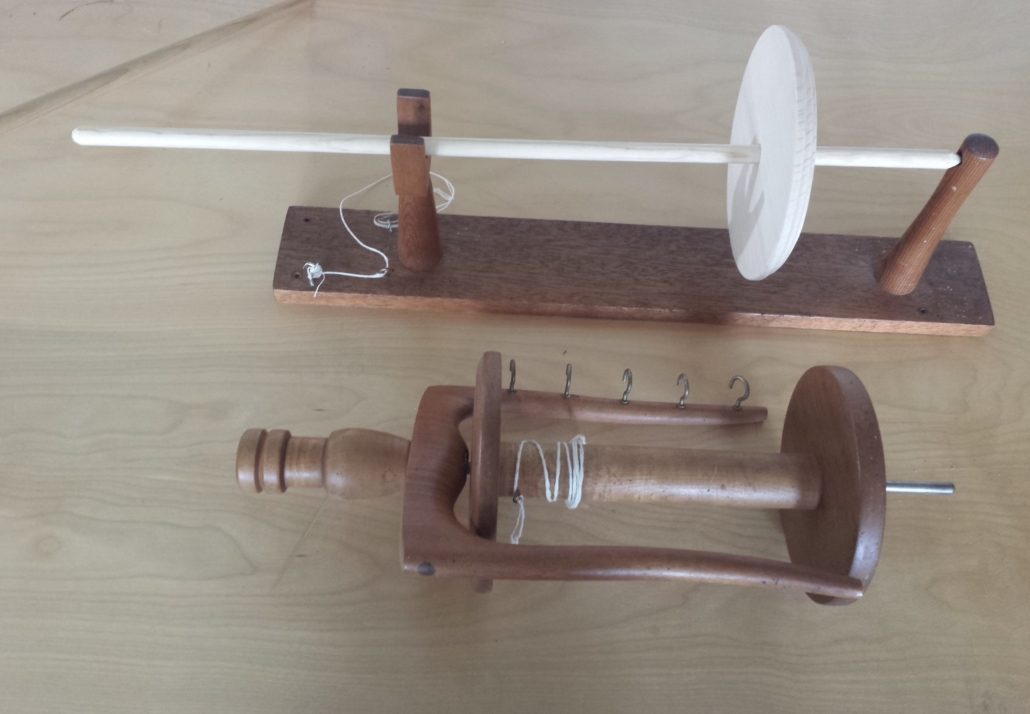

Along with sheep, settlers brought treadle sewing machines. The Coast Salish, knowing their large spindles made thick warm wool, cleverly attached their spindle to where a sewing machine would sit, added a groove on the whorl to hold the drive band and a fork to hold the other end of the spindle, and spun using the treadle machine. This became known as the Indian Head Spinner or what Ashford called the Country Spinner.

Farming their own flocks

The imported sheep were mostly Merino and cross-breed Cheviot-Leicester with some purebred Southdown, Cheviot, and Leicester. By the 1880s the Cowichan Coast Salish were farming their own flocks. These were the perfect breeds for creating Cowichan sweaters. The high crimp in these fleeces create a bulky yet lightweight and bouncy yarn. The air pockets between the fibres provide warmth. If wool fibres have a lot of crimp, the fibres will push against each other, causing the yarn to puff out and creating many air pockets to capture and keep air, creating a warm yarn. If the fibres are mixed in a jumble (woolen) rather than lying parallel (worsted), the puffier the yarn will be.

Most sheep produce lanolin which provides the animal with waterproofing. The finer the fibre, the more lanolin on the sheep. Most of the sheep imported were fine or medium breeds which produce good quantities of lanolin. On the west coast where rainfall is plentiful, having sheep with good lanolin to protect them is an advantage. If the fleece is washed with lukewarm water rather than hot, some lanolin is left in, and when spun, the yarn will retain some waterproofing qualities. Fishermen not only wore Cowichan sweaters for warmth but also wore Cowichan long johns!

The fleece qualities of high crimp and lanolin are why the Cowichan sweaters were made famous – a lightweight, warm, and waterproof sweater. The sweaters were so famous that the Coast Salish have had to fight battles with fashion houses that appropriated the Coast Salish designs for company profits and no benefit to the Coast Salish.

Making Cowichan-like yarn

While you can never make a true Cowichan yarn unless you are Coast Salish and integrate your culture into the process, you can make a Cowichan-like yarn using modern equipment. But remember to respect and acknowledge the Coast Salish tradition of spinning and knitting Cowichan or Salish sweaters. Be creative, and design a yarn to provide the same good qualities of Coast Salish yarn. Colour it bold or colour it subtle, but make it yours.

If you want to make a Cowichan-like yarn, start with a good crimpy fibre and spin it in the grease or gently wash it in warm, not hot, water to remove the dirt and leave some lanolin in it. You can also start with scoured wool and add lanolin before you spin or once the garment is finished by adding lanolin to a bath as you full or finish the garment. Paradise Fibers has a great instructional tutorial on how to do this.

You need to create a woolen yarn, so prepare the wool by creating rolags. Some spinning wheels are designed for spinning bulky yarns, e.g., the Ashford Country Spinner, wheels made for art yarns (Louet), those with jumbo or bulky-head attachments (Lendrum), and those with bobbin-led flyers with large bobbin capacity. But even if you don’t have one of these types of wheels, you can make do with a wheel designed for medium yarns. The Scottish-style and double-drive wheels are designed for lace yarns; hence, they have small bobbins and might give you an airy, warm, but much much thinner yarn.

Choose your largest whorl; it should have a low ratio such as 4:1 or 6:1. Wheels with a large orifice and large flyer hooks are best as you are trying to spin thick yarns. However, thick does not mean dense. You are aiming for light, lofty, big bouncy yarns. Keep the air pockets in the yarn. A thick yarn can squeeze down and fit through a smaller orifice if necessary, but it should bounce back to bulky and not impede your spinning.

Bulky yarns need little twist, especially if you are starting with good crimpy, grabby fleece. If you have a bobbin-led wheel (the drive band turns the bobbin), put a lot of tension on the drive belt. Higher tension will practically grab the fibres out of your hand and onto the bobbin quickly. If you have a flyer-led wheel (the drive band turns the flyer), loosen the brake on the bobbin. Twist will build up quickly, so let it onto the bobbin even before you think it has enough twist. By the time it gets wound on, it will have enough twist. (Check out Michelle Boyd’s article “The Truth about Take-up” in the Summer 2016 issue of PLY for more information.)

Spin, as Paula Simmons describes in her classic book Spinning for Softness and Speed, using an unsupported long-draw technique. This is often a zen-like one-handed technique. Hold the rolag in one hand. Pinch off about an inch and pull the hand away from the orifice after allowing the twist to build up a little, grabbing and twisting the loose fibres to the thickness you are looking for. Keep tension on the fibres and let the twist chase your hand steadily, gobbling up the wool as you pull back to your side. Treadle slowly and then gracefully return your hand to the orifice and repeat. Relax, breath slowly, treadle slowly, and enjoy the Zen of it.

Some people suggest you pre-draft a roving to the thickness you want and let it run onto the bobbin with barely any twist. This will get you a bulky yarn but not a lightweight one. It will instead be heavy and dense, full of fibres but not air. Remember, for this yarn you want to let the air into the yarn.

If you do not have a low ratio whorl or end up with too much twist, one of our spinning saints, Judith MacKenzie, has a trick: spin a thick yarn and do not worry about putting in too much twist. Once you have filled the bobbin, take it off your spinner, put it on the floor, and run it through your spinner very quickly in the opposite direction to take out some of the extra twist.

You can use the yarn as a singles yarn or ply it. Traditionally, the Coast Salish plied the yarn for their blankets but made Cowichan sweaters from a singles yarn. If it is a singles yarn you are looking for, avoid weighting the yarn to set the twist as you are really stretching it and losing the lofty bulk you want to keep. Instead, finish them boldly in hot soapy water, agitating before plunging the yarn into cold water. You are trying to bloom or full the yarn, not felt it, but full it enough that it creates a slightly protective web around it to prevent easy pilling. Alternatively, you can full the finished product. Whichever you do, think about trying to maintain or add some lanolin to the final soaking to give the end product some weatherproofing if wanted.

Further reading

Gibson-Roberts, Priscilla A. Salish Indian Sweaters: A Pacific Northwest Tradition. Saint Paul, MN: Dos Tejedoras Fiber Arts Publications, 1989.

Gustafson, Paula. Salish Weaving. Seattle: Douglas & McIntyre, 1980.

Simmons, Paula. Spinning for Softness and Speed. Madrona Pub, 1982.

Every time Liz Hammond-Kaarremaa, a Master Spinner, sees a Coast Salish blanket or sweater, the world stands still for just a moment, but packed into that moment are many women’s lives: the spinner, her children teasing and carding, the carvers of her spindles and looms, and the ceremonies where the blanket or sweater was worn. These objects radiate those moments. Visit her website for more resources.

PLY Magazine believes that Black lives matter, as well as LBGTQI+ lives. Those most vulnerable and persecuted in our communities deserve our love and support. Please be good to each other.

This was an excellent well balanced article full of information and respect for the northwest native culture

Thanks Leslie,

I am glad you enjoyed it. Isn’t the word ‘respect’ so important in this day and age even within cultures. I am sure we could solve more of the worlds problems by respecting each other and the planet more. Thanks for reading!

Liz

Hi! Thank you so much for this insightful article – I love learning about the variety of different spinning cultures around the globe.

One question though for clarification: shouldn‘t I TIGHTEN the break on my flyer-led wheel in order to achieve the same effect as tightening the drive-band on a bobbin-led wheel (having the fibers grabbed out of my hand)? Thanks! All the best, Carola

Hi Carola, yes, I think you are correct, if you TIGHTEN the break on the bobbin (Scotch/flyer-led wheel) you will get fast take-up and less twist. If you TIGHTEN the drive band on a bobbin-led wheel (aka Irish) you will get a stronger take-up and less twist. If you can’t adjust the drive band on a bobbin-led wheel, then slow the flyer by increasing the brake on the flyer to get less twist.

All this talk of different systems TWISTS my mind! If others have suggestions please jump in.

The other factor that people should consider is the tension they put on the fibre as they draft it out. You are going to do a long draw so you are pulling the rolag back to your side so you need enough tension to pull against. At the same time you don’t want to pull yarn off the bobbin, yet when you are ready to wind it onto the bobbin you need it to pull the yarn in. It’s a delicate balance. Basically the brake friction (on a flyer-led bobbin) needs to slip to allow the yarn to form as you pull back, but grip when you want to wind on. To achieve the right balance I play with my long bobbin lead that I use to start the fibres. I hold on to it and adjust my brake so I can pull the yarn out and yet when I stop pulling, the bobbin has just enough drag to pull it back on. I hope that doesn’t confuse things 😉

Liz HK

Hi, Liz!

Thanks for replying. No confusion – you basically confirmed my experience, and that‘s reassuring 🙂

Best wishes,

Carola