Tweaking My E-Spinner for Angora

words and photos by Terry Clemo

“I’m not new at this spinning thing,” I think to myself. “Why am I having such a strange beginner experience with my new Ashford E-3 electric spinner?” After setting up my new machine, I start to play with some dyed wool. I didn’t think changing from a manual, foot-driven spinning wheel to a little electric spinner would be such a challenge. But it has been, and not for the reasons one might think. I’m not missing the treadling; in fact, I’m so happy to be able to put my legs up. I’m so much more comfortable now – hey, I can spin in bed!

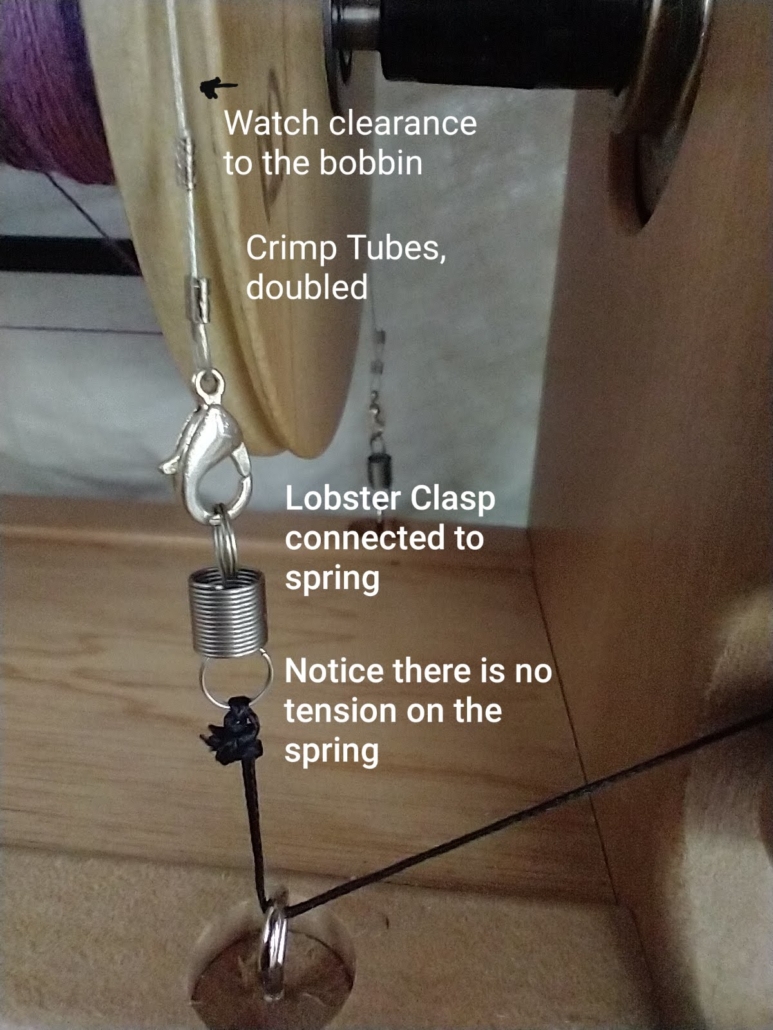

“So what’s your problem,” you might ask. Well, I’m having trouble getting my spun yarn to wind on, and when I stop, the bobbin keeps turning and the single wraps around the bobbin and is going the wrong way. Ugh, now to unwind and correct the path of my spun single. I’ve not ever had the bobbin on my double treadle Lendrum do that before. “Hmmm, Lendrum bobbins are so little looking compared to the jumbo bobbins that came with the new E-3.” I’m not used to their weight turning around with the flyer either. So I slightly tighten up the Scotch tension to make a bit more resistance on the bobbin and try again. Same thing happens, so I add a tiny bit more tension, and the draw in of the single is starting to work, but just barely. Okay, now maybe I can get somewhere.

At the same time I’m playing with the speed controller of the flyer to see how it reacts with my takeup. It’s adding another variable to my dilemma. In comparison, both spinners are flyer-led and have Scotch tension, but why are they behaving so differently? Time for a cocktail. The DT Lendrum has the drive band on the flyer, and when I press the treadle I get the immediate response of the flyer turning. The E-3 has the centre spindle of the flyer resting in a keyed bushing that is the centre hub of the motor, so I have to turn up the speed dial to get it turning. As I’m playing with the speed control, I find it needs to be turned up almost to 15–20% to get the flyer to move when I have some resistance on the single and so that there is some torque force to be able to pull the single so it wants to wind on.

By now I’m using more flyer speed and more tension, and the bobbin stops after spinning. But now there’s too much pull for my liking and I can’t get the amount of twist into my single that I need before it wants to be swallowed by the orifice. Normally, I would back off the tension, but I can’t really; there doesn’t seem to be a sweet spot. I can’t fine tune this setup with the original heavy, stiff fishing line that came with the machine. And I’m not spinning with a grabby fibre or a short draw, which might help get this spinner working well.

Side journey through angora spinning

You see, my spinning journey flourished at the same time my love of very fuzzy rabbits was fulfilled. My first angora was an English that I named Flurry. She was “fur in a hurry”! Needless to say, pretty much all of my spinning has something to do with angora from rabbits.

My favorite thing is to spin angora from a cloud (which is basically a fluffed up, or carded, small handful of airy angora fibre, which can be organized or not); it can be so magical. I especially like how the tips of the individual fibres protrude and spiral out from the centre of the single when they are drawn out and not smoothed down. It’s exactly what blooming spun angora should look like. This texture is accentuated by the long draw.

Angora is a finicky fibre; the more you fuss with it – try to handcard it or blend it with itself or other fibres – the more likely you are to put more nepps in it than it had from off the rabbit. Since angora is so fine (in the range from 7–8 microns to mid-teens, with an average of 10–12 microns), it easily tangles. Also, the average staple length is 4–7 inches for the blanket of the rabbit, the longest fur from their back, and unless its harvested correctly, it can get new tangles in it. Angora bunnies also have some lovely textured fur on their chest, belly, and legs; it’s shorter at 2–3 inches or so and it’s not as dark as the top side colour, mostly. As you spin their fibre, there will be colour changes as you go because the colour varies on the bunny. This colour changing ability is quite beautiful and gives angora yarns their character.

Some angora spinners don’t mix the two basic types, mostly because of the length difference, but colour differences can be the main reason. For some of my spinning projects, having both can make the yarn more textured, and it will be fuzzier. My favourite way to spin is straight from the storage box, loose and fluffy whatever comes so I may end up with some shorter fibres mixed with longer silkier ones. So I try to fluff up and mix the two so I hold a couple of staple lengths at the base with my thumbs and fingers and I pull apart from so it separates into one layer in each hand. I lay it back on top of the other layer, hold the base end, pull it apart, and this time I put the new layer on the bottom. I’ll put many of these little bundles aside in a smooth container to spin later.

I like my angora spun with tiny slubs and uneven blending, and with a long draw technique that lends to loose airy preparations. So with my long draw technique, I need some tension to pull against to draft out the fibres as the twist is holding everything together just enough to be a thread.

Back to the e-spinner

So my secret is out, I’m a long draw girl. Now I get to play around with my new toy and translate this style of long draw to the e-spinner. I need to have very little take-up tension while I’m drafting so my single doesn’t prematurely feed onto the bobbin before it gets sufficient twist. The single when using short draft is basically always moving through the orifice, but not with a long draw. My long draw draft is about 14–16 inches, so there’s a lag in time before I can wind on. I don’t want the flyer to pull too hard and pull apart the newly forming single. I like to use a supported long draw. My right hand helps me control twist to the cloud of fiber and gives me something to pull (draft) against. I stop drafting to let my twist come into the single and I visually check for my chosen angle of twist and then slowly push the thread into the orifice, and the bobbin starts to wind the single and it seems to gather a bit of momentum till I stop. Leaving my leader out with extra twist building up in it and again having very little draw in, I start drafting out again.

So after all this is said, remember that I’m spinning Angora at 100 percent or about 20–25 percent in a blend with very fine wool (22 microns or less) and silk or maybe some alpaca or other fine fibres. Angora is very slippery, hence the very light takeup on the bobbin, and it lets me get more twist in my single. I usually spin from laceweight to fingering weight, so I’m spinning fine. My plies for my yarns are made of one or two singles of angora and the others are a blend of dyed wools, silks, and angora or dyed wool, all the while playing with colours. Depending on the project and how much angora I want, I can use different combinations of these, but I usually stick to 2 or 3 plies per yarn.

How do I fix my dilemma as to how to make this machine work the way I need it to?

Planning my attack, depending on how and what I wanted to spin, I could use cords of different materials for the brake band to give more slipperiness. I might try a finer nylon filament or the plastic coated stainless steel jewellery wire, some nylon threads, or high end fishing lines made of plies from titanium or other advanced materials. I also wanted to try adding a bit more drag to increase tension and help with spin-on of the bobbin, so I’ve tried cords that were a bit rough like hemp (thin and thick) and whatever else I could think of. I’ve even tried something similar to the traditional cotton. I tried the string that sealed the rabbit feed bags, which seemed to be more slippery than the usual cotton. It’s probably a form of polyester, which is more durable than the cotton. The diameter of a cord also comes into play. I need to be able to quickly snap different brake bands into place to find my favourite band.

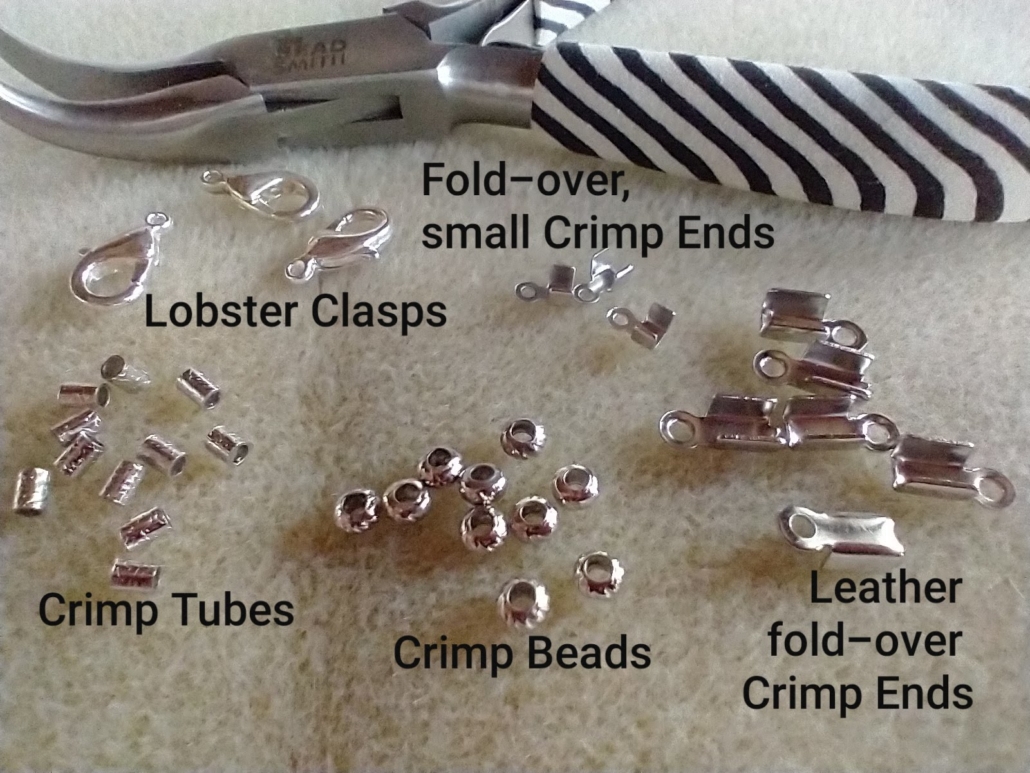

I realized that if I wanted to experiment with different bands it wasn’t going to be so easy to untie knots attached to the springs. I decided to make different quick-connect brake bands. I used small lobster clasps approximately 10mm and crimps beads or tubes, 1.5mm size. I also had foldover crimp ends (with connector eye) in various sizes, which would close better with crimpers.

So far, my favourite band over the rabbit feed bag string was the plastic coated multi-filament beading wire. It’s quite fine and seems to give me varying degrees of tension that I didn’t have before. Like any journey, I’m still playing around with different cords and different fibre blends. There’s not enough time in a day or a week for that matter to ever have enough spinning time.

Terry Clemo has had soft spot for fuzzy animals from a very young age. It seemed to follow that her interests spanned to other fibre arts like knitting and sewing and other textural crafts while still a child. Her mother was an expert machine knitter and told her she needed to hand knit before she would give her any machine knitting lessons. With the lessons came a toolbox of techniques that opened up the door to designing her own knitting patterns. Working with her luscious angora, Terry makes batts, handspun yarns, and semi-precious beaded wire knitting jewellery such as shawl pins. You can find Terry on Facebook and Instagram and at various fibre events.

Did you know we also have a monthly PLY newsletter? Sign up here!

PLY Magazine believes that Black lives matter, as well as LBGTQI+ lives. Those most vulnerable and persecuted in our communities deserve our love and support. Please be good to each other.

Leave a Reply

Want to join the discussion?Feel free to contribute!